A Tin Can Making Machine is a machine that produces cans. These cans are used for a variety of different purposes and can be made from a wide range of materials, including aluminum and other processed metals.

The main purpose of these cans is to hold liquids such as beverages, chemicals and food products. However, they can also be used as containers for other items.

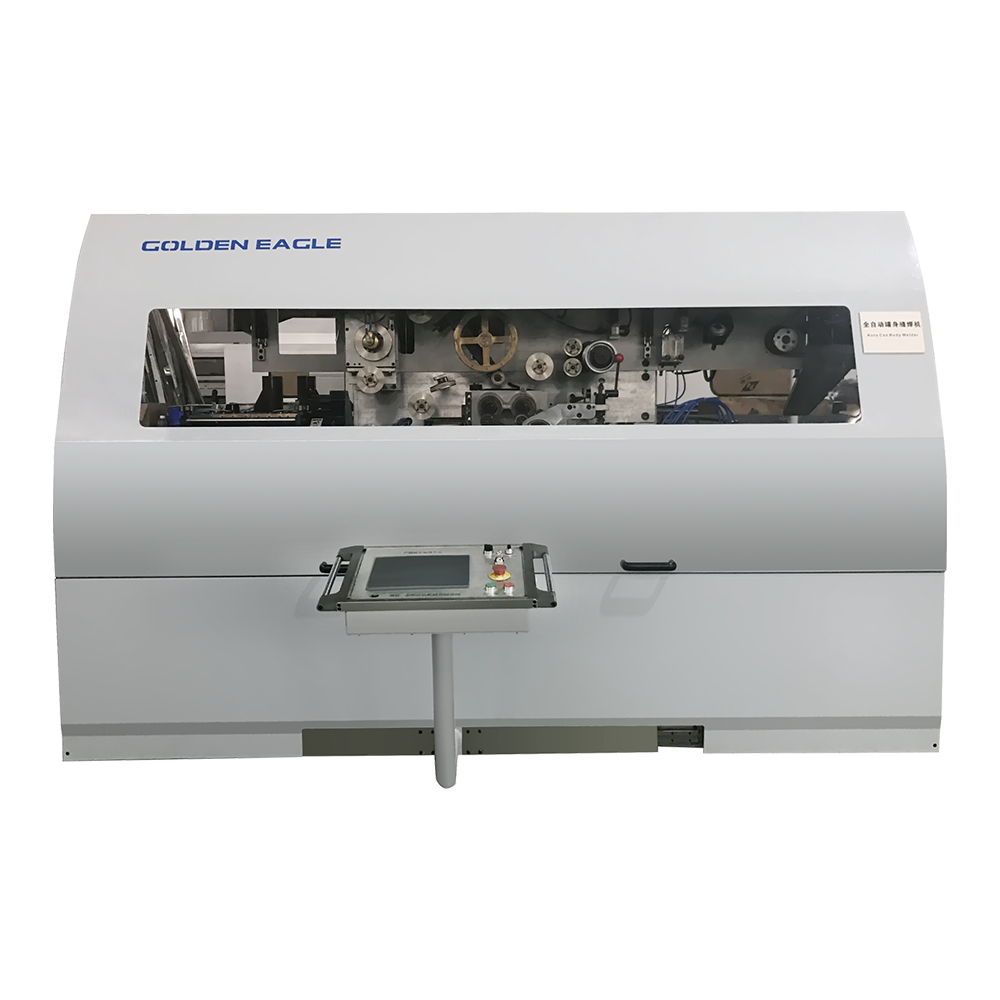

These cans are produced using a process that involves slitting and welding. These processes are typically performed on a multi-functional slitter that can cut printed or lacquered metal sheets into body blanks of various sizes and shapes.

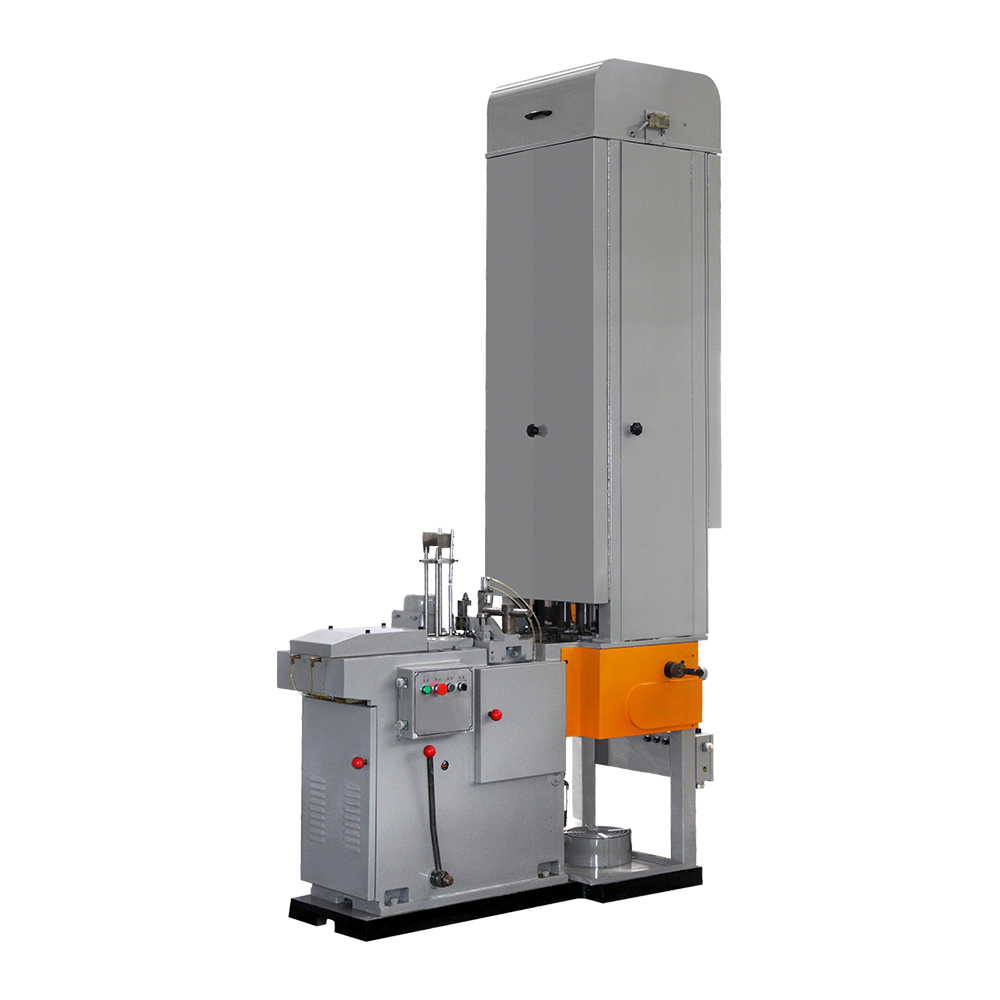

This slitter also has the ability to feed the sheets automatically, vertical or horizontal cutting and duplex detection. It is an important piece of equipment that must be selected carefully as it plays a very important role in the production process.

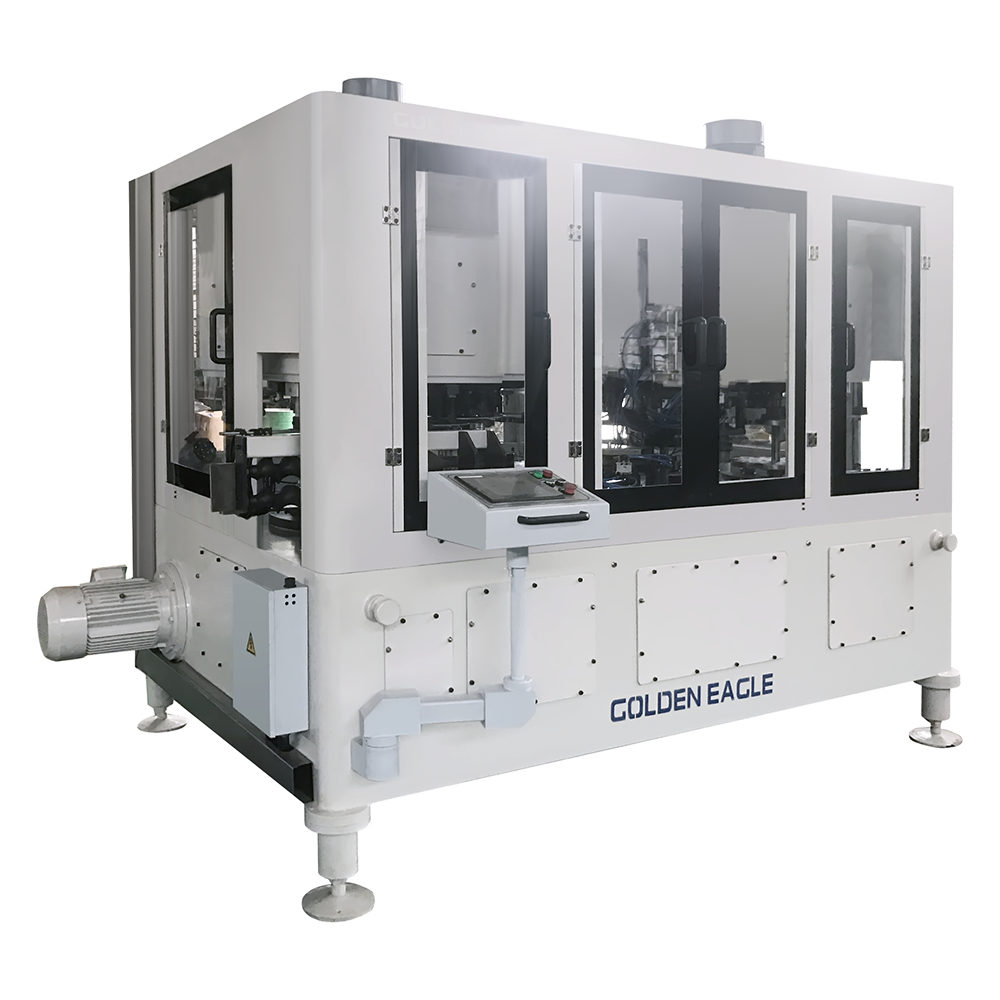

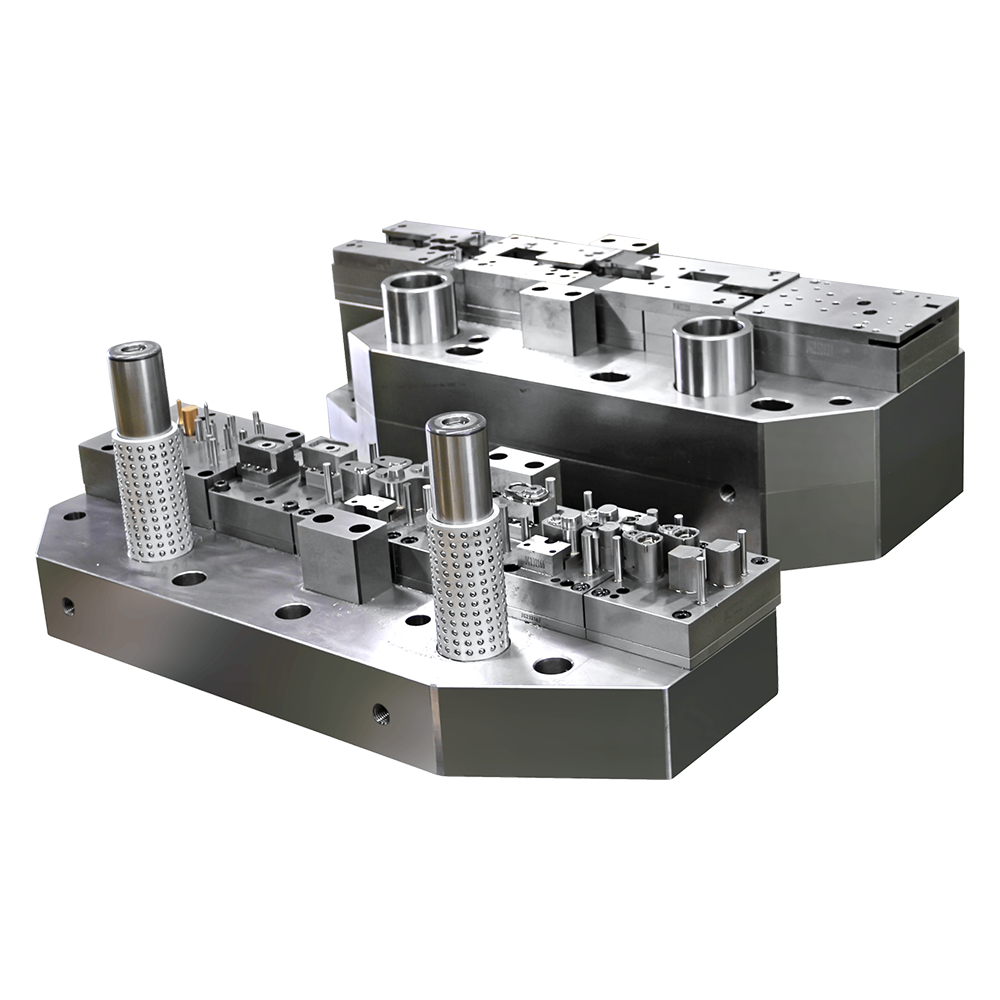

Next, the slitted sheets are then fed into a sheet shear which cuts them into smaller scroll sheets. These scroll sheets are then sent to the end forming press which stamps them into finished ends. The finished ends are then packed into tubes for delivery to the fabricating plant or customer.

Another important component of a can making machine is the quality and ease of use that it offers. This can be determined by how easy it is to operate and the way in which it is designed.

A good quality tin can making machine should not be difficult to operate and will require little or no technical knowledge to use. This will ensure that the machine runs smoothly and will be able to produce great results.

Often, there are several types of tin can making machines available and you will want to find one that suits your particular needs. You will also want to take into account the reputation of the firm that you are purchasing from as this can play a huge role in determining the quality and ease of use of the machine that you are looking for.

Some tin can making machines also come with an in-line leak tester which can be used to check the quality of the cans that you are producing. This is a great feature as it means that you can make sure that all the cans that are manufactured and shipped out are high-quality ones.

The other factor that you will need to look at is the type of labor that the machine uses. This is because you need to ensure that the machine that you are buying can be used effectively by the people that will be running it.

You will also want to consider the warranty that is offered as this can be a key deciding factor in whether or not you choose to purchase a tin can making machine. This can be an essential consideration as it will ensure that you are not left out of pocket if anything goes wrong with the product that you are manufacturing and it will also make sure that you are able to receive help from a trusted source.

2-lanes D109-D211 Aerosol Cone Lid Line

Operation: Automatic

Can Size:Φ45-65mm

Speed: 240epm 2-lanes