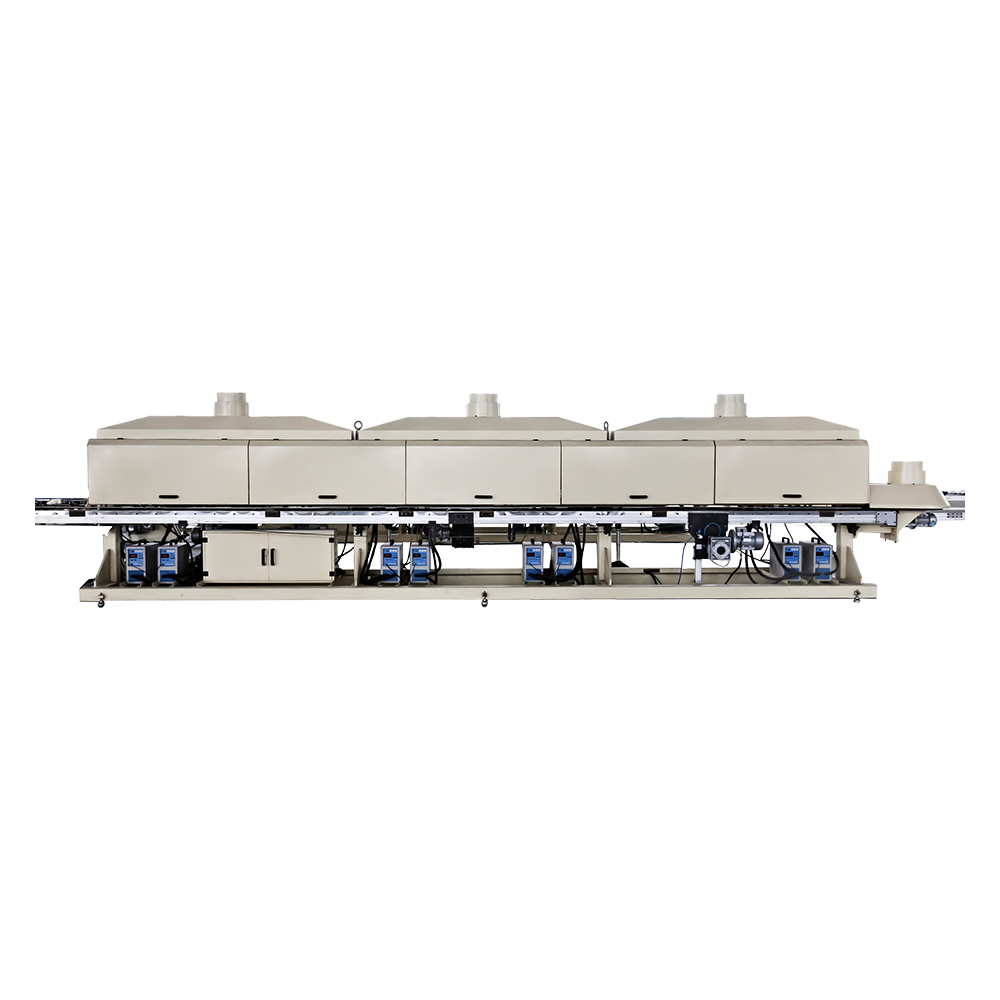

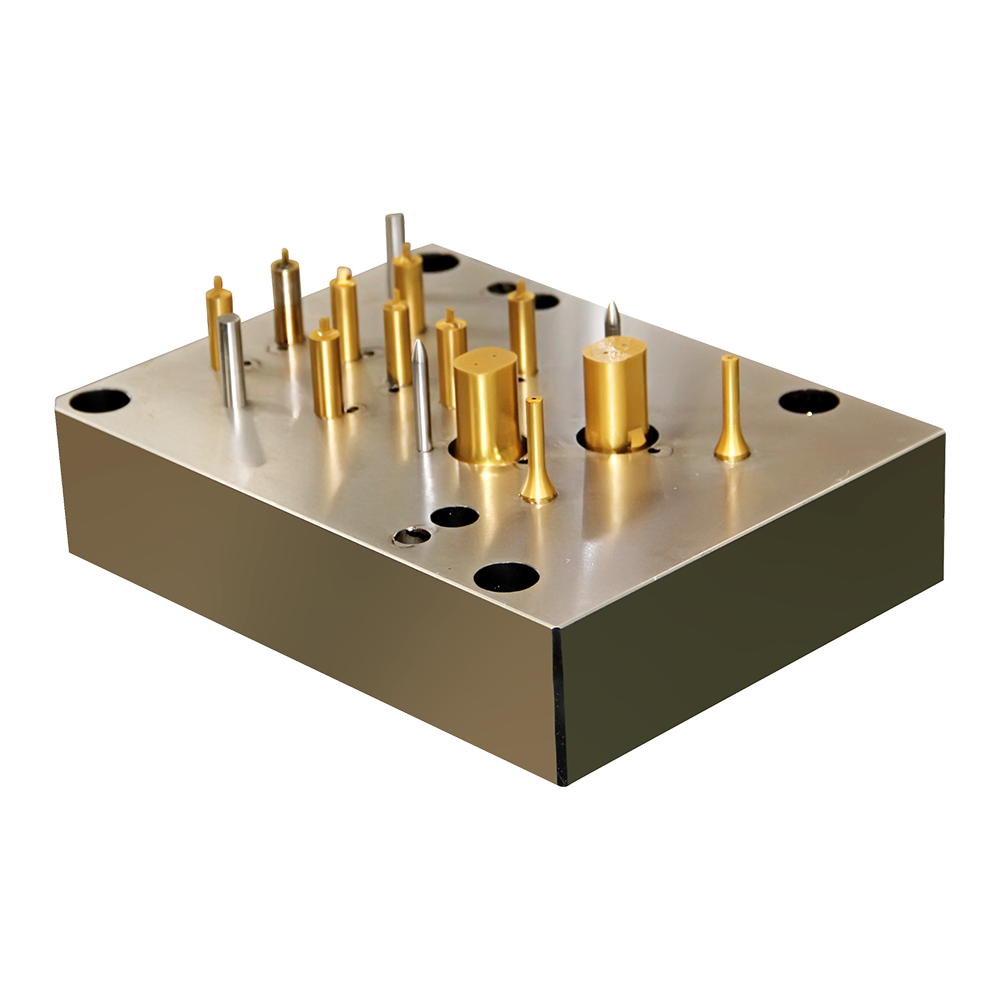

We have adopted multiple unique designs and advanced technologies to improve the production efficiency of EOE Lids Making Machine. We have optimized the overall layout and workflow of the machine, improving the smoothness and coherence of the production line by reducing unnecessary material handling and waiting time. For example, we have designed an automatic feeding system and intelligent buffer zone to ensure continuous supply of materials during the processing, avoiding production interruptions caused by material shortages or waiting.

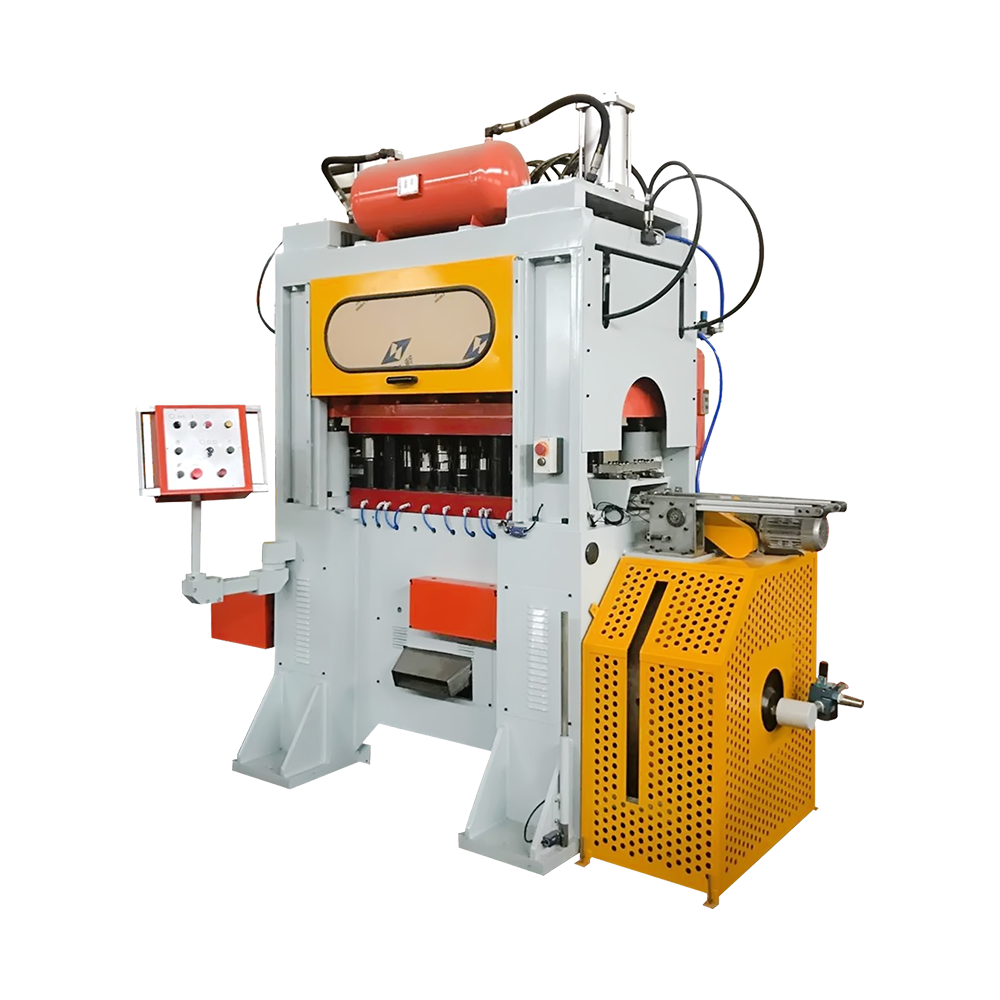

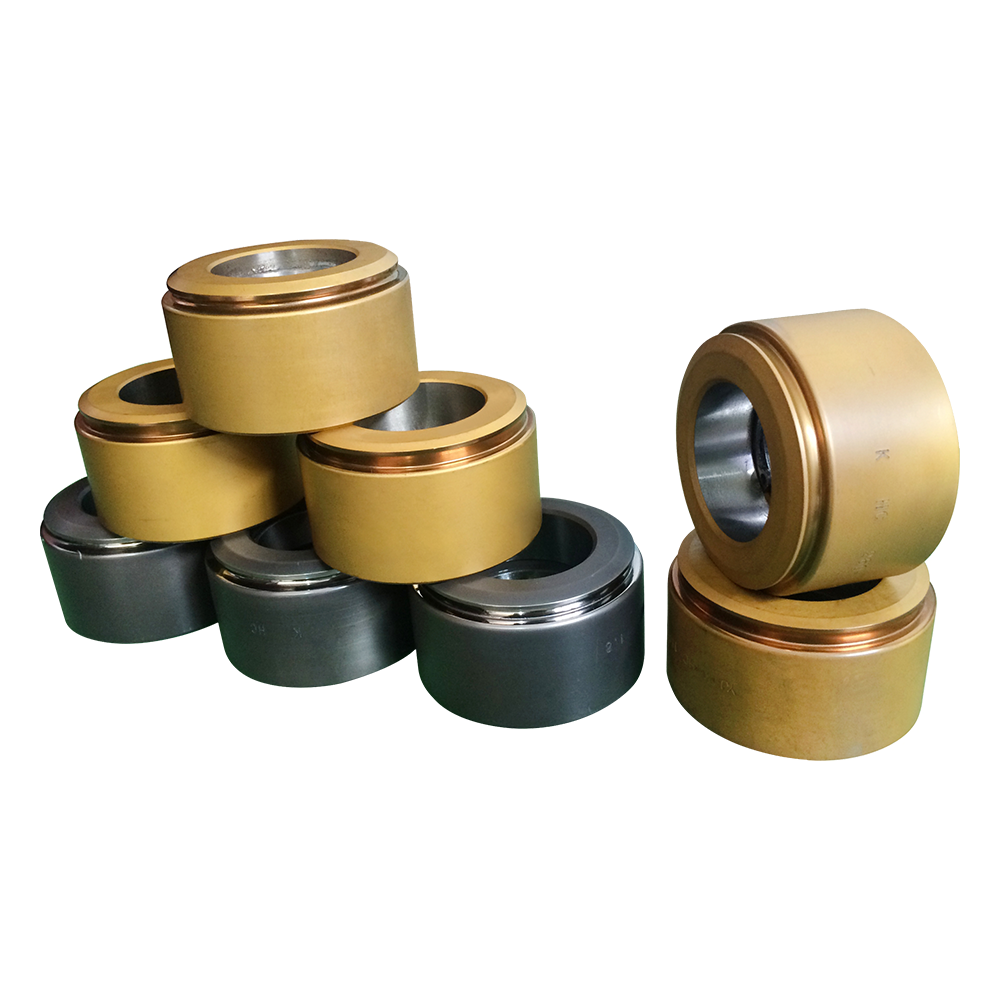

We have introduced high-speed servo motors and precision transmission systems, providing powerful power and precise control capabilities for the machines. These systems ensure that the machine remains stable and precise even at high speeds, greatly improving production efficiency. At the same time, we also adopt advanced variable frequency speed regulation technology, which can adjust the running speed of the machine in real time according to production needs to achieve the best production effect.

In addition, we also focus on the intelligence and automation level of machines. By integrating advanced PLC control system and touch screen human-machine interface, we have achieved comprehensive monitoring and remote control of the machine. Users can set production parameters, monitor production status, and receive fault alarm information through a simple operation interface, greatly improving the convenience and production efficiency of operations. At the same time, we also provide rich extension interfaces and communication protocols, which facilitate users to connect machines to larger automated production lines and achieve more efficient collaborative operations.