The Aerosol Cone&Dome Making process faces many technical difficulties, including material selection and processing, precise control of shape and size, assurance of sealing performance, and improvement of production efficiency. To overcome these challenges, manufacturers have adopted various advanced technologies and processes.

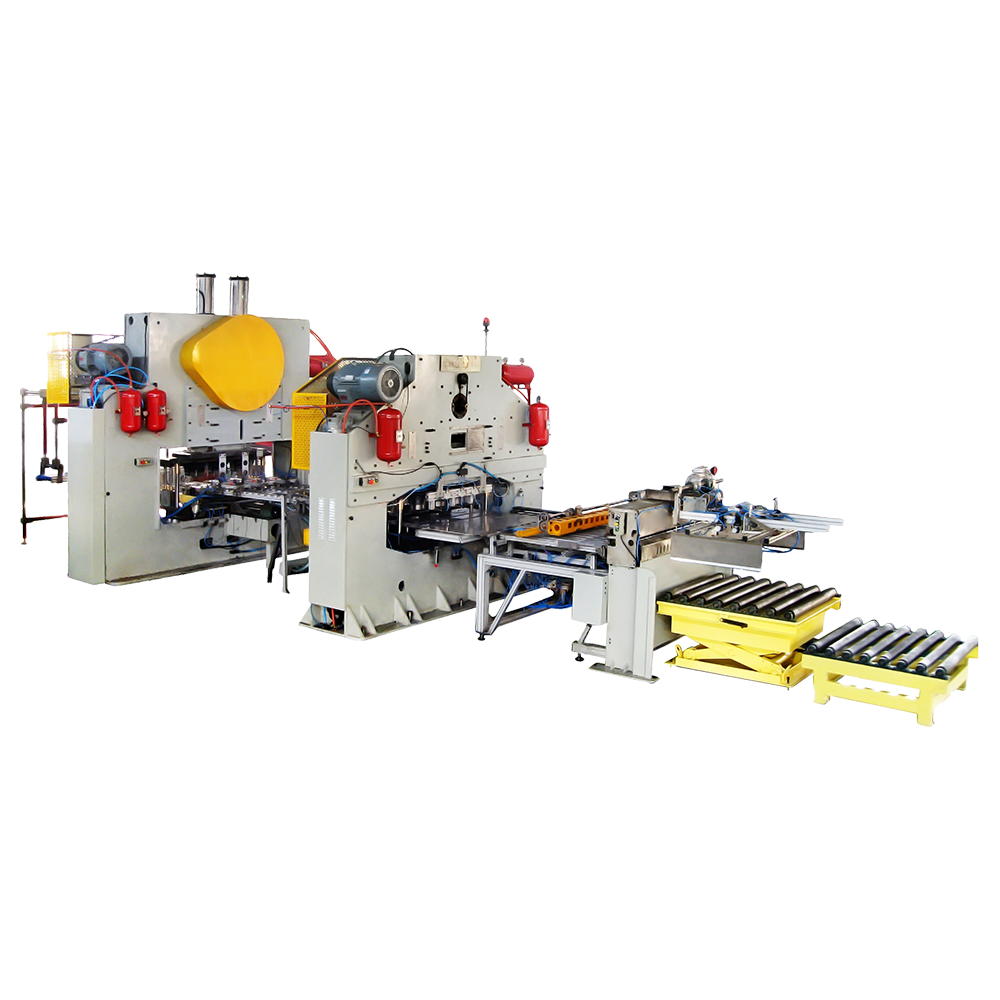

Firstly, in terms of material selection and processing, manufacturers will choose suitable metal sheets or composite materials based on the specific needs of the product, and process them into the desired shape and size through precision stamping, embossing, and other processes. At the same time, in order to improve material utilization and reduce costs, manufacturers will continuously optimize production processes and procedures.

Secondly, in terms of precise control of shape and size, manufacturers use high-precision molds and advanced CNC equipment to ensure the dimensional accuracy and shape consistency of the top cover. In addition, they will conduct strict quality testing and screening on the finished products to ensure that every product meets the standards.

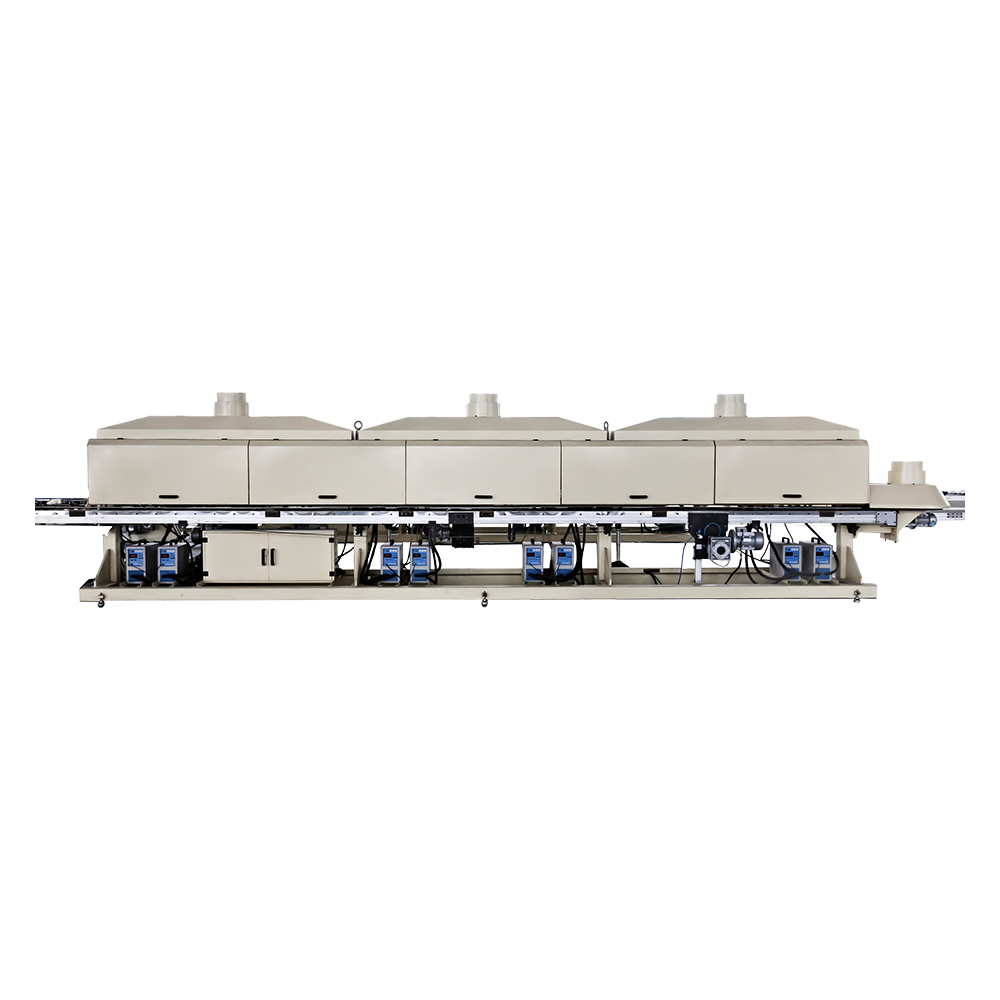

Furthermore, in order to improve sealing performance and production efficiency, manufacturers will continuously optimize the design and structure of the top cover, and adopt automated production lines and intelligent control systems to reduce the impact of human factors. These measures not only improve production efficiency and product quality, but also reduce production costs and energy consumption.