The primary components of a 2-lanes D109-D211 Aerosol Cone Lid Line typically include:

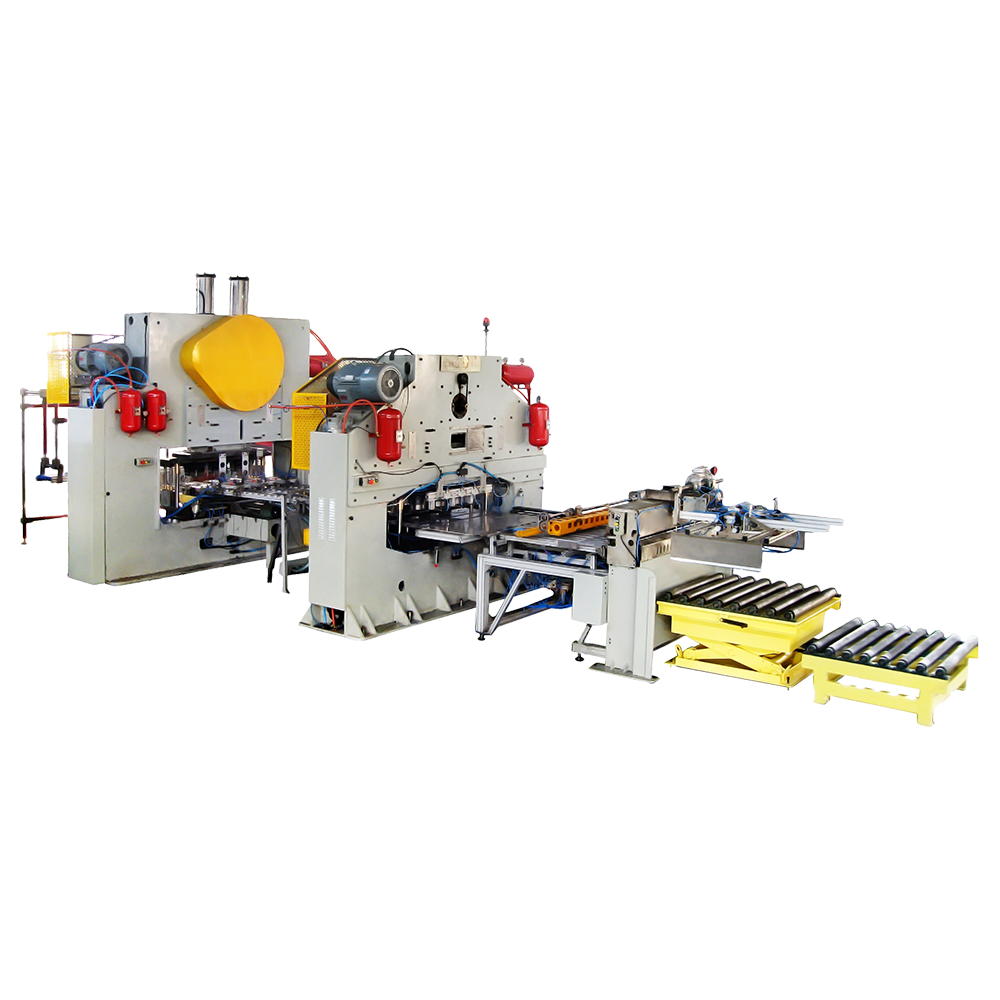

Feeding System: This is where the raw materials, usually in the form of metal or plastic sheets, are fed into the machine for processing.

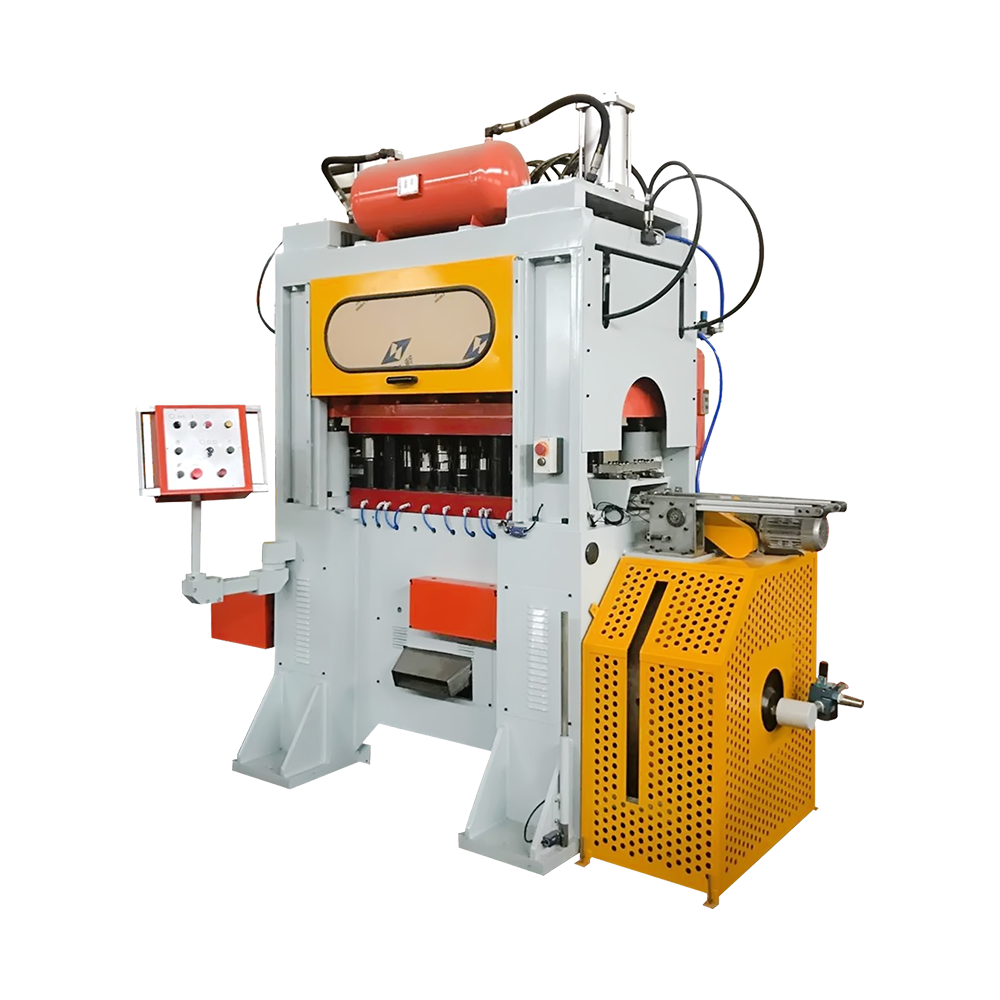

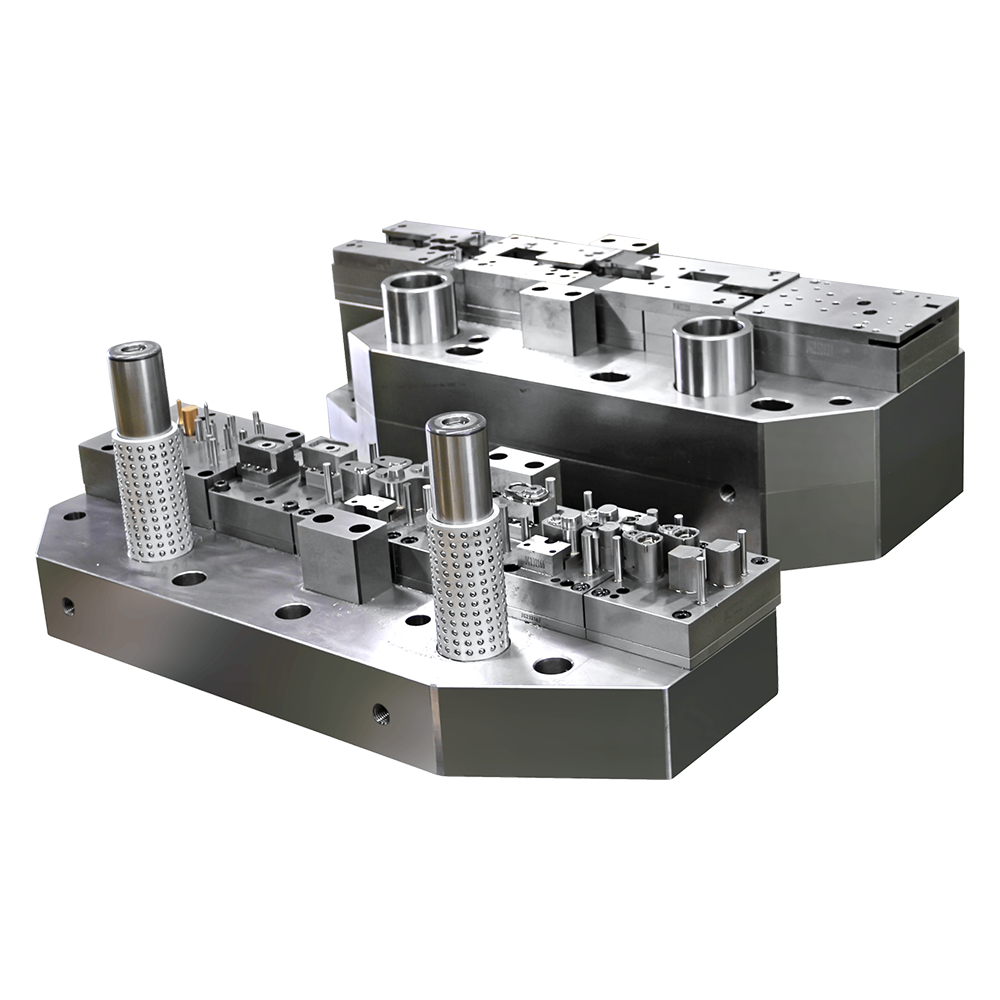

Forming Station: This station forms the flat material into the shape of aerosol cone lids. It can involve various processes such as stamping, pressing, or molding.

Cutting Station: This station cuts the formed lids from the continuous sheet material. It may use cutting dies or laser cutting technology for precision cutting.

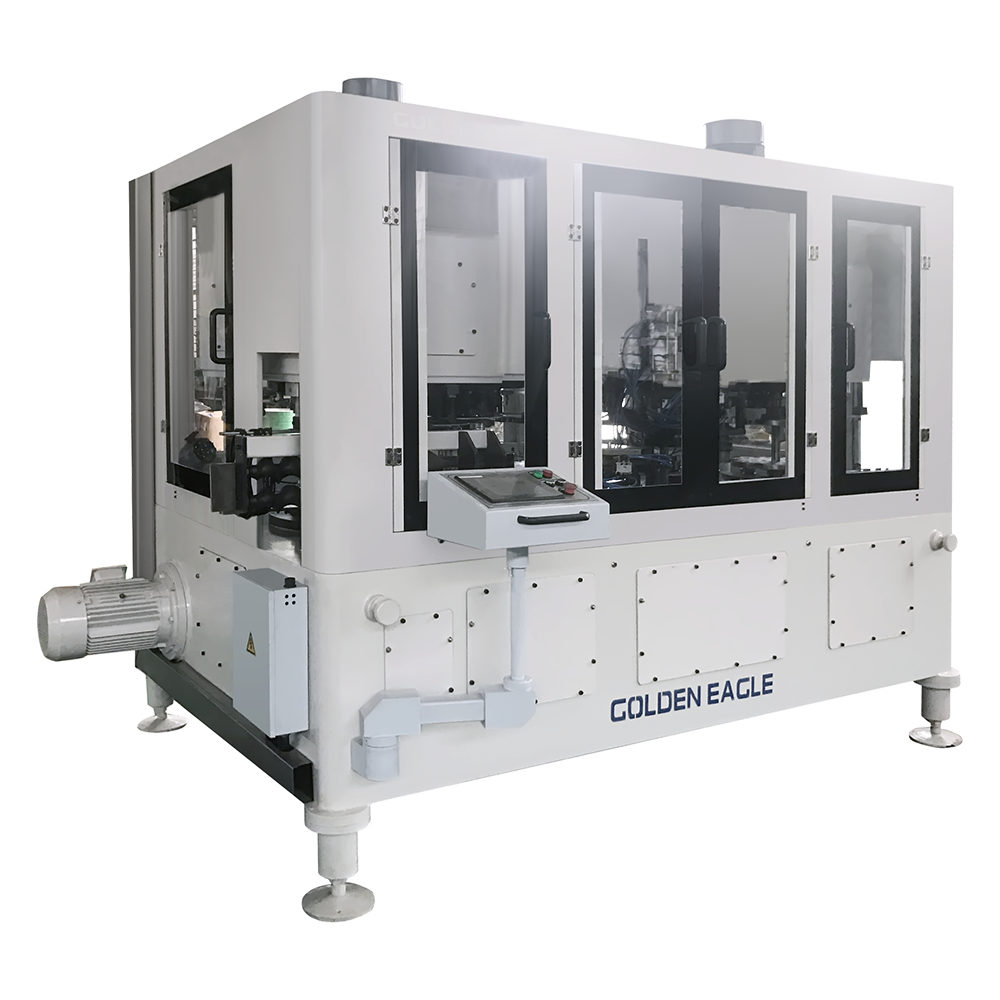

Trimming Station: After cutting, any excess material or flash is trimmed off the lids to ensure they meet quality standards.

Quality Inspection Station: This station checks the dimensions, shape, and quality of the lids to ensure they meet the required specifications. It may include sensors, cameras, or manual inspection stations.

Stacking and Sorting System: Once inspected, the lids are stacked and sorted for packaging. This can involve conveyor belts, robotic arms, or other automated systems.

Packaging Station: This is where the lids are packaged into boxes or other containers for shipping. It may include labeling, sealing, and palletizing equipment.

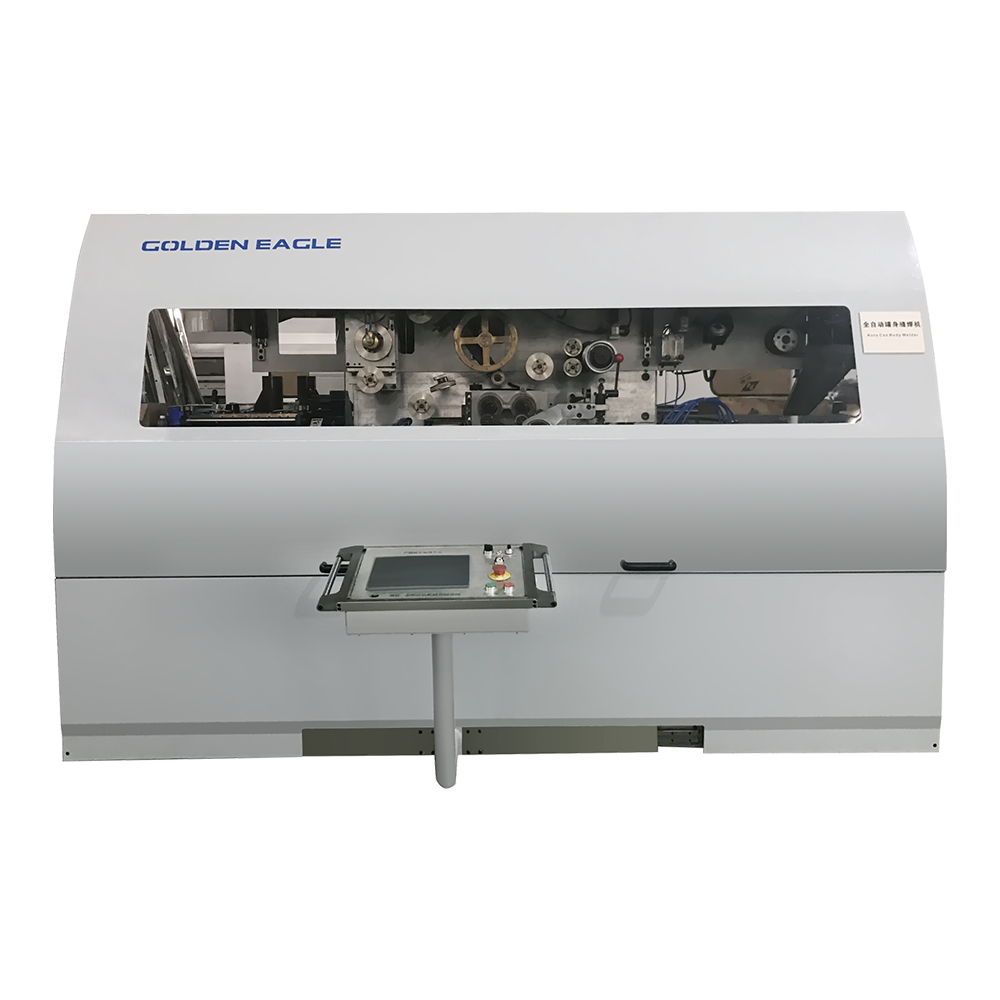

Control Panel and HMI (Human-Machine Interface): A control panel with an HMI allows operators to monitor and control the lid line's operation. It provides access to settings, diagnostics, and production data.

Safety Features: These can include emergency stop buttons, safety guards, light curtains, and safety interlocks to protect operators and ensure safe operation.

Conveyor System: Conveyor belts or other transport systems move the lids between stations and through the production line.

Electrical and Pneumatic Systems: These provide power, control, and actuation for the various components of the lid line.

Cooling or Heating Systems: Depending on the material and manufacturing process, cooling or heating systems may be used to maintain the material's temperature during forming and shaping.

Waste Management System: A system for collecting and disposing of waste material or recycling scrap material generated during production.

These components work together to automate the production of aerosol cone lids, ensuring efficiency, consistency, and quality throughout the manufacturing process.