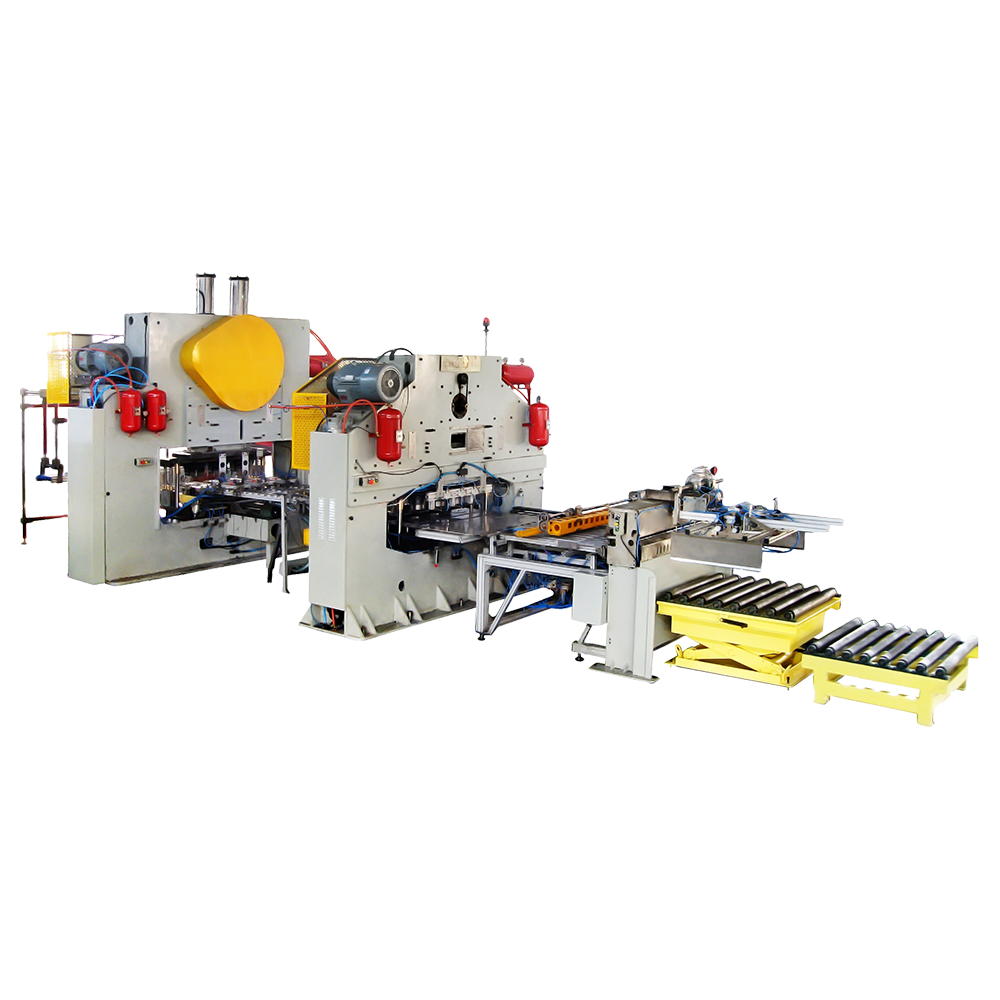

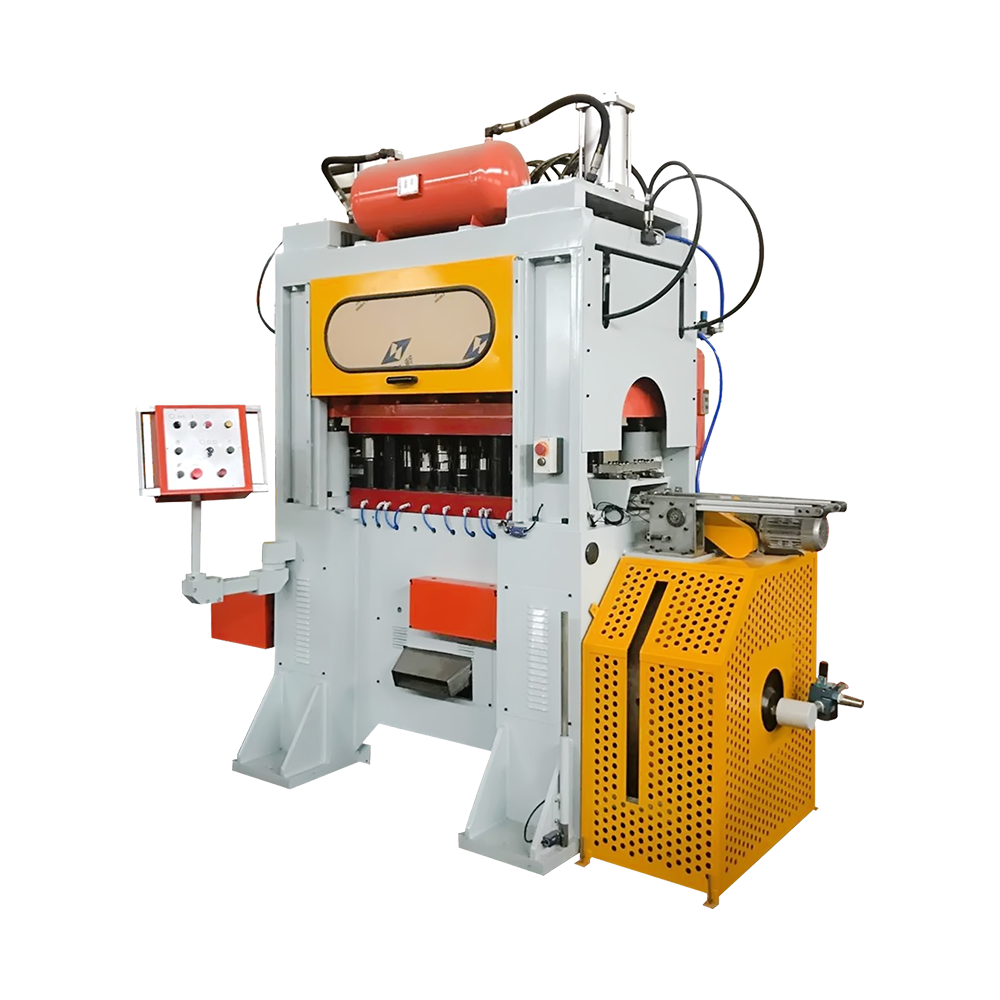

The new can sealing machine supports the can diameter range Φ52-99mm, and the height range H40-60mm (after cutting). This wide range of adaptation enables it to meet diverse product requirements, whether it is food cans or industrial cans. At the same time, this equipment has extremely high production capacity, providing a standard production speed of 20-100cpm, and can even reach a high-efficiency mode of 80-300cpm, bringing strong power to the production line.

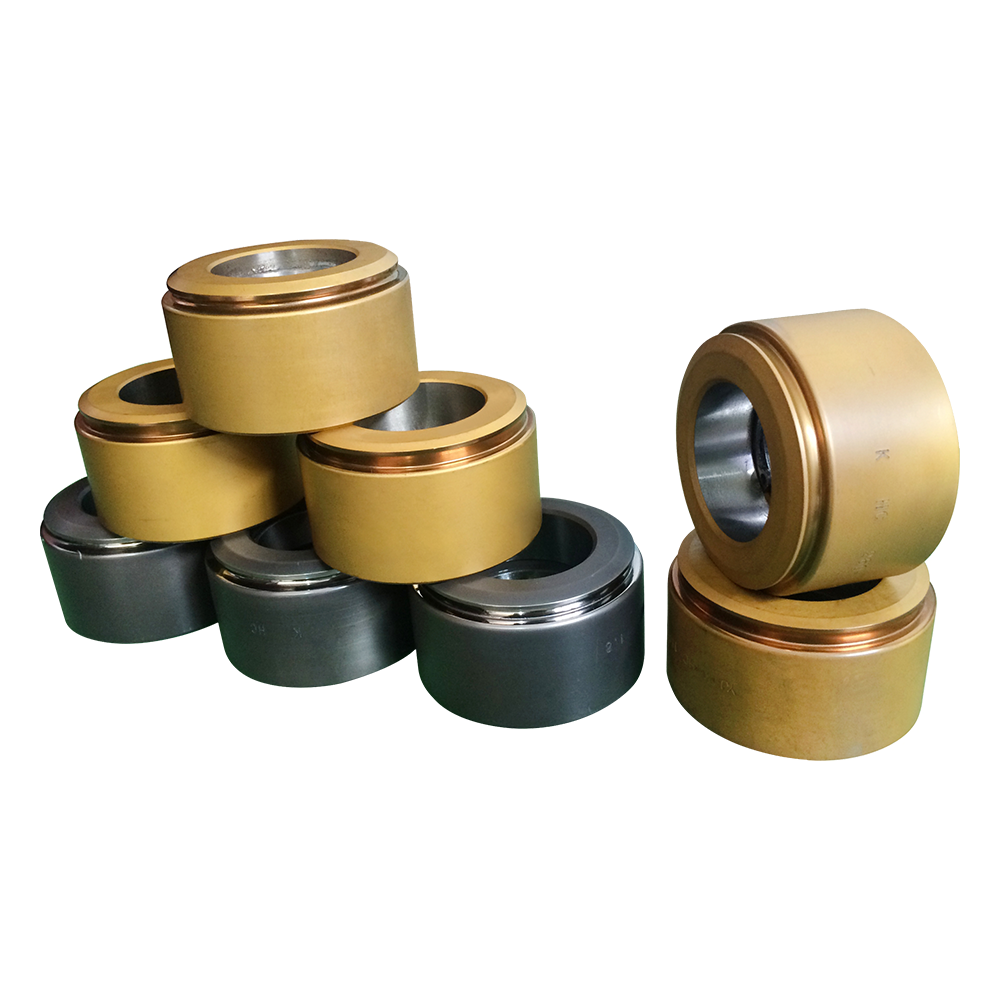

The core functionality of the equipment lies in its precision cutting technology and single-station design. The cutting part adopts a high-precision control system to ensure that the height of each tank is consistent and the cut is smooth, minimizing errors. The application of this technology can not only significantly improve the aesthetics of the can, but also improve the sealing performance during the subsequent can sealing process, providing double guarantee for product quality.

In addition, the equipment’s single-station design further optimizes the operating process. Compared with traditional multi-station can sealing machines, the single-station design focuses more on flexibility and floor space savings, making it very suitable for small and medium-sized production companies and customized production scenarios. At the same time, the modular structure design makes equipment maintenance and component replacement more convenient, significantly reducing downtime and maintenance costs.

In practical applications, the device demonstrates strong adaptability and reliability. A food company that was the first to trial this equipment said that the new can sealing machine not only significantly improved production efficiency, but also successfully reduced the defective rate of products and resource waste through its precise cutting and sealing performance, further improving the company's competitiveness.