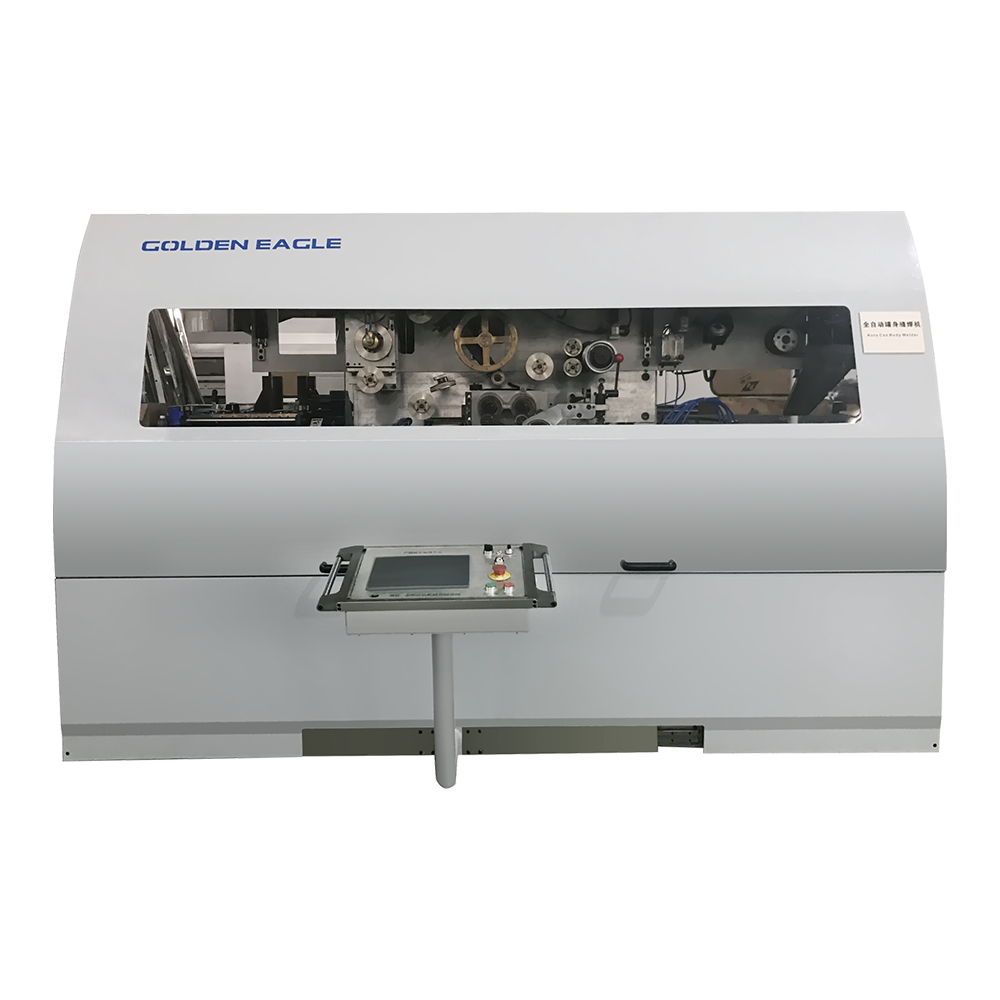

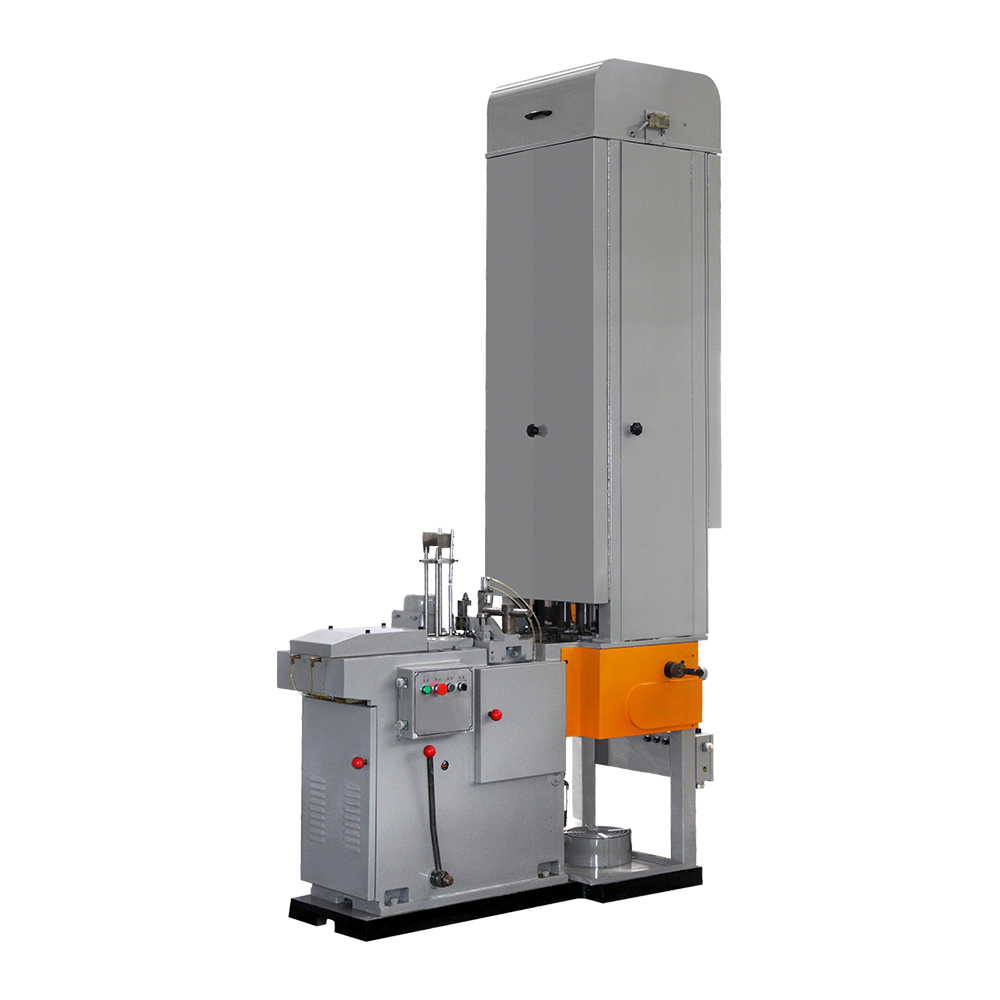

The Post-Repair Machine for EOE Scorelines is specifically designed to restore and enhance the score lines of easy open ends, ensuring that the packaging meets the highest standards for usability. This innovative machinery is set to redefine repair processes by combining advanced technology with user-friendly features.

One of the standout features of the Post-Repair Machine is its automatic operation, which significantly reduces the risk of human error and increases overall production speed. Once set up, the machine operates seamlessly, requiring minimal supervision while maintaining high-quality repair results. This automation feature not only enhances consistency in production but also contributes to the efficiency of the manufacturing process.

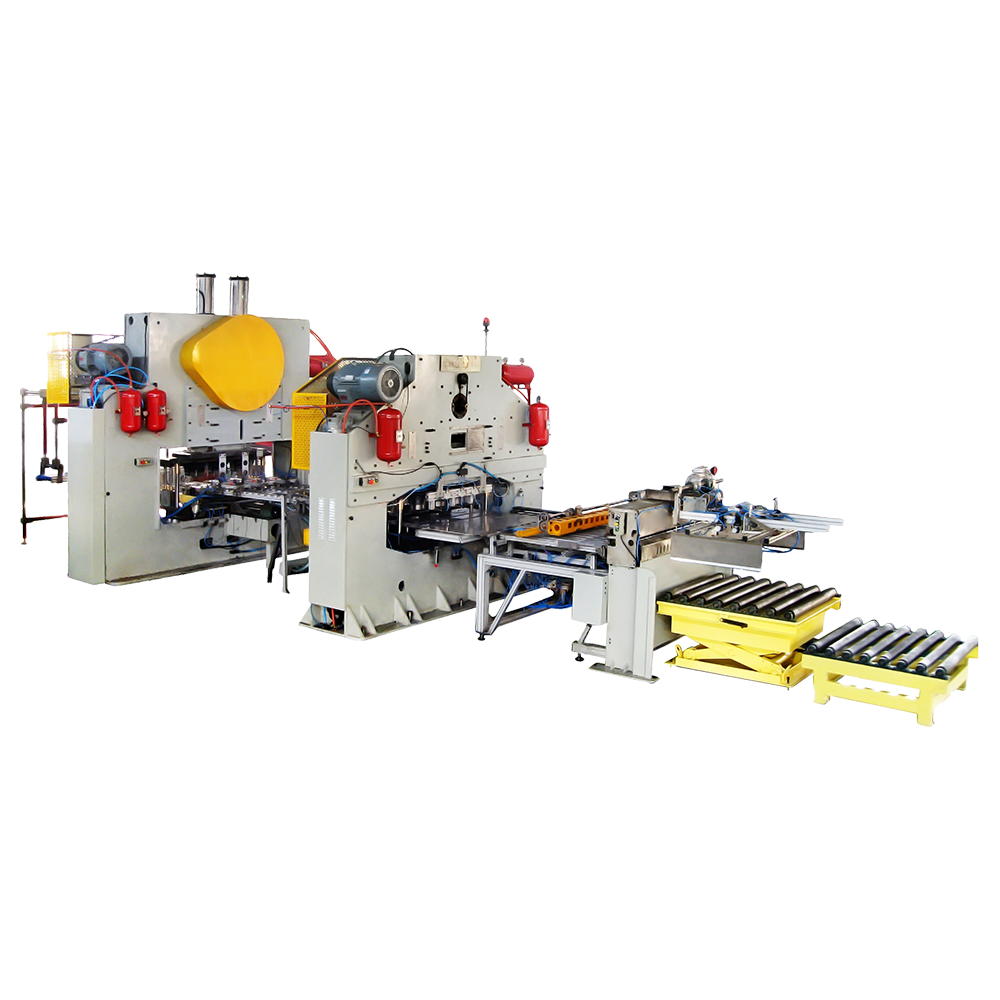

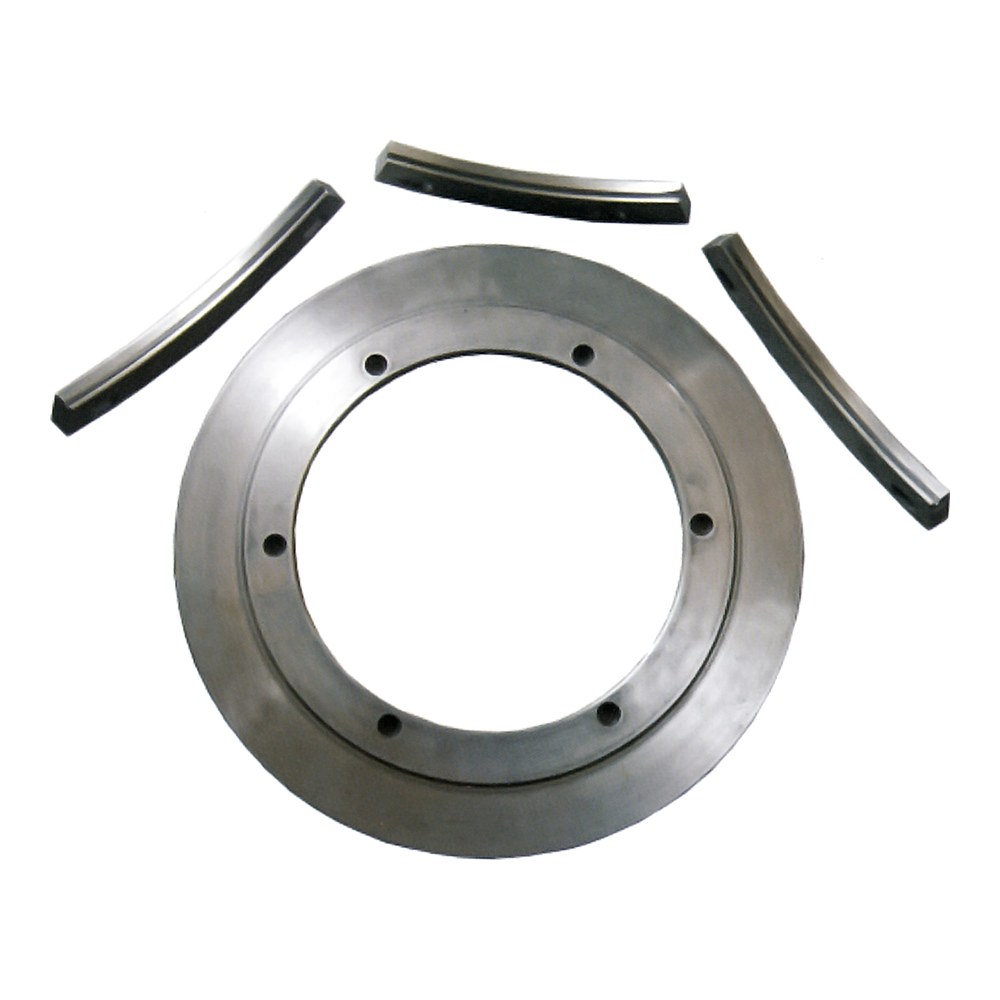

Another remarkable advantage of this machine is its ability to accommodate various can sizes and types. The machine is versatile, capable of repairing score lines for a wide range of easy open end sizes, from 200 to 401 diameter (D). This adaptability makes it an ideal solution for manufacturers dealing with diverse product lines and varying customer requests. Whether for small or large production batches, the Post-Repair Machine ensures precise repair of the score lines, regardless of the can size or type.

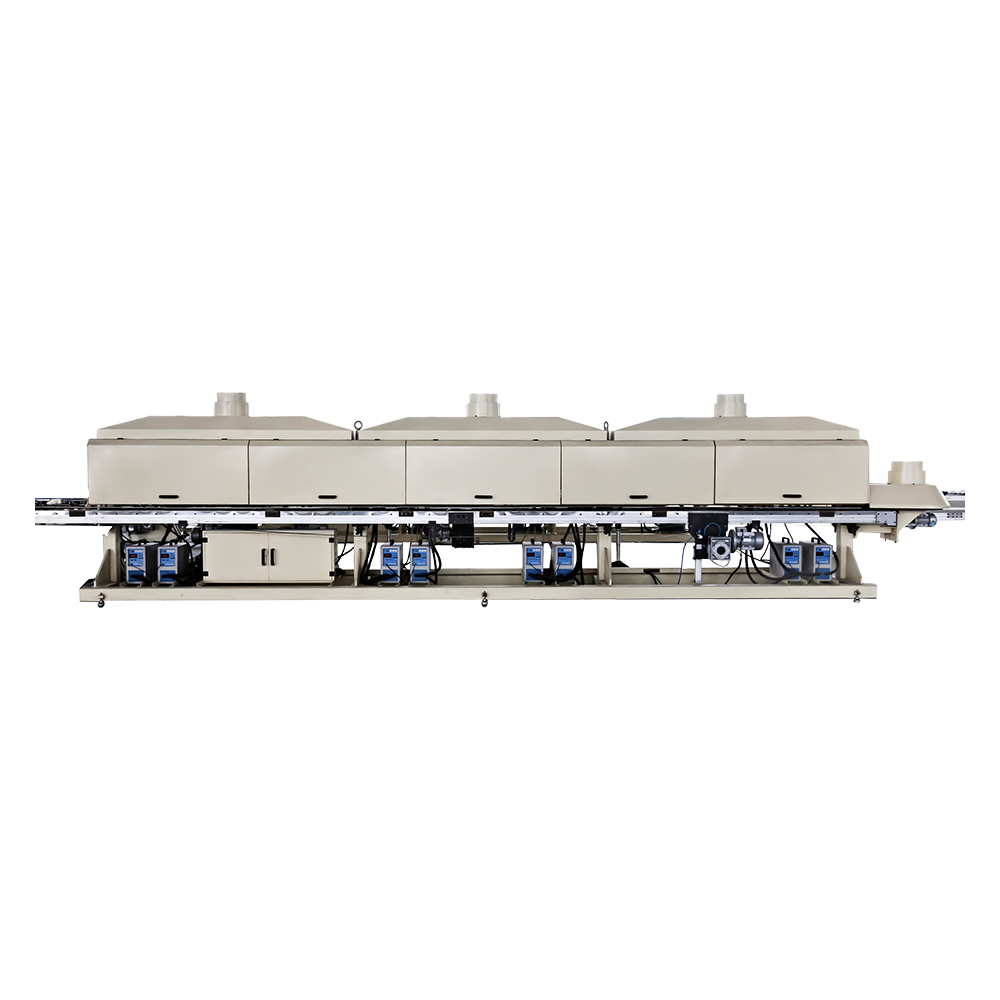

Manufacturers will also appreciate the low power consumption of the Post-Repair Machine. In an industry where energy costs can significantly impact the bottom line, the machine’s efficient power usage helps reduce operational costs, making it a cost-effective investment for long-term production. The combination of reduced energy consumption and automated operation allows manufacturers to achieve optimal performance while keeping overhead costs to a minimum.

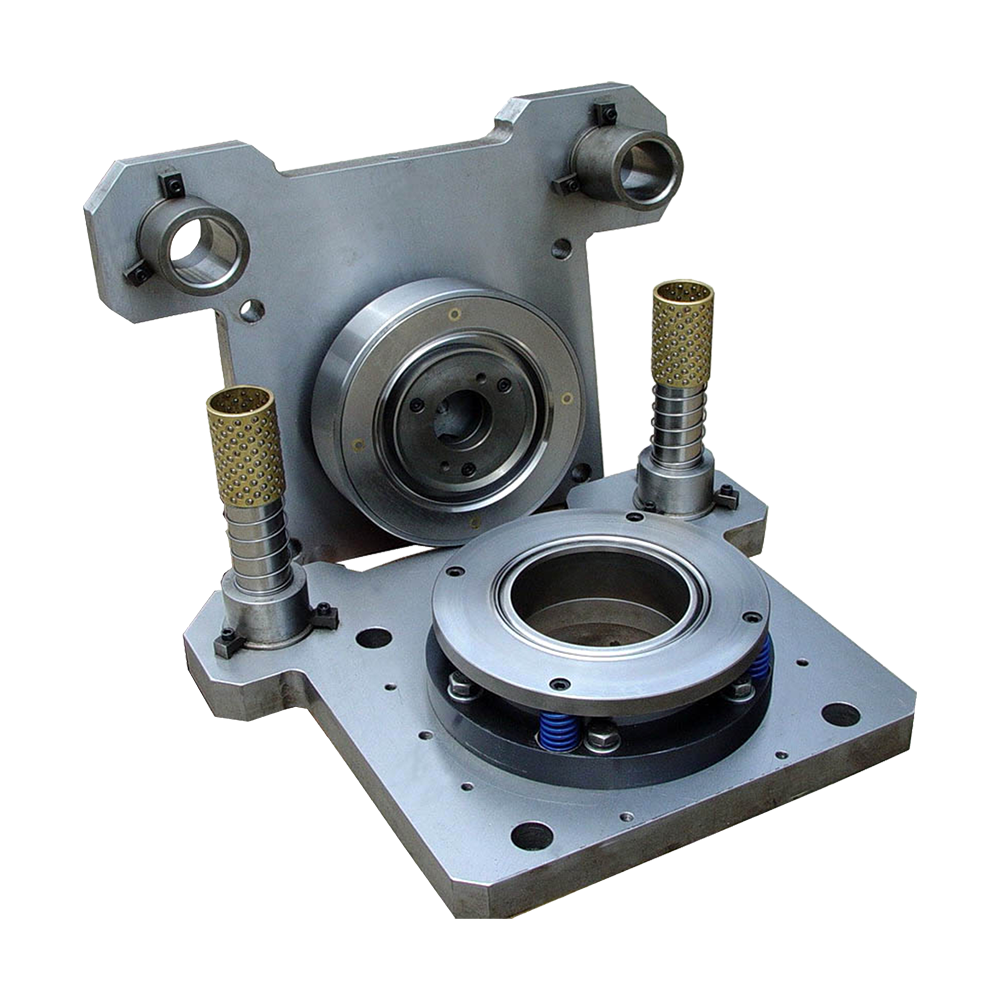

Maintenance is another key consideration for manufacturers, and the Post-Repair Machine excels in this area as well. Designed for easy upkeep, the machine features a simplified maintenance system that allows for quick adjustments and repairs when needed. This ease of maintenance ensures that production downtime is minimized, contributing to uninterrupted manufacturing operations and reducing the risk of delays in meeting customer demands.

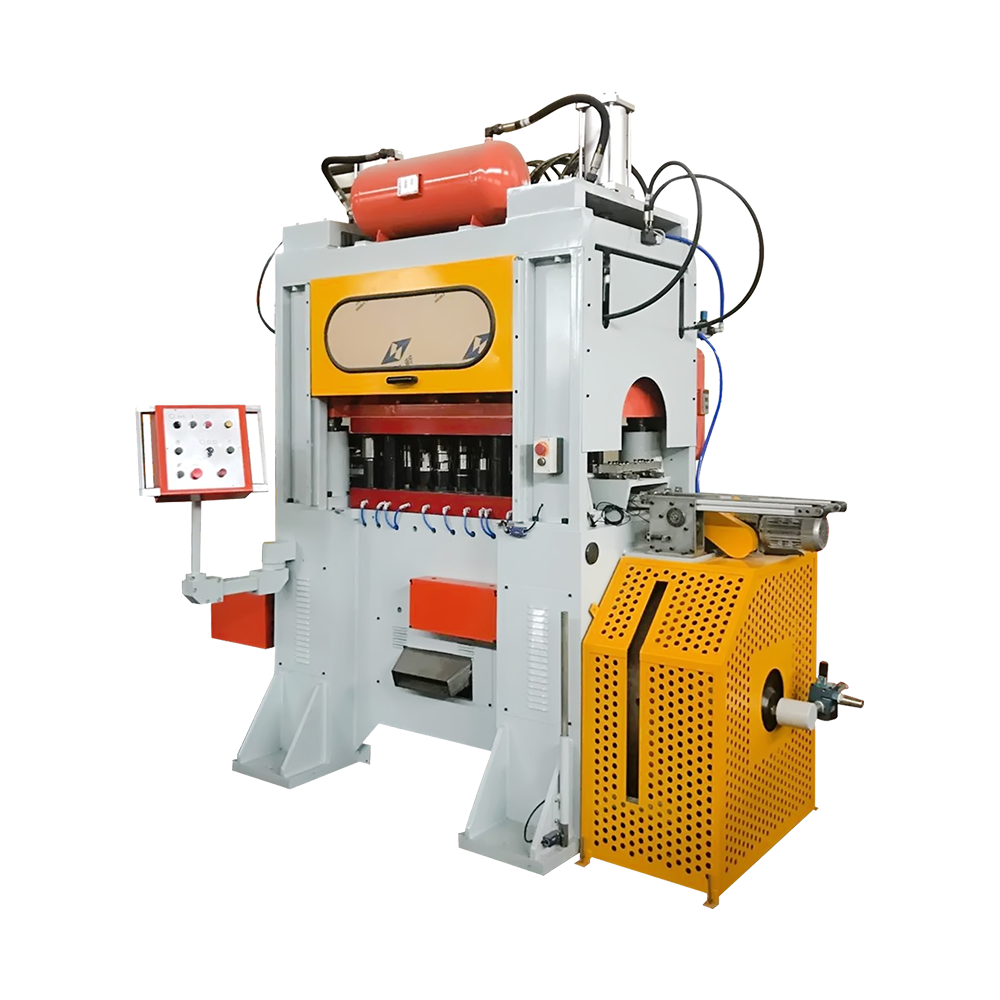

Additionally, the speed of the Post-Repair Machine is tailor-made according to specific customer requirements. Depending on the needs of the production line, the machine can be adjusted to operate at a custom speed, providing a flexible solution for varying production volumes. Whether high-speed production is required for larger orders or slower operation is needed for more intricate repairs, the machine adapts to ensure optimal output.