In terms of improving production efficiency and reducing costs, TIN CAN LID END MAKING MACHINEhas adopted multiple innovative technologies and solutions. These technologies and solutions not only improve production speed and quality, but also effectively reduce energy consumption and labor costs, bringing significant economic benefits to customers.

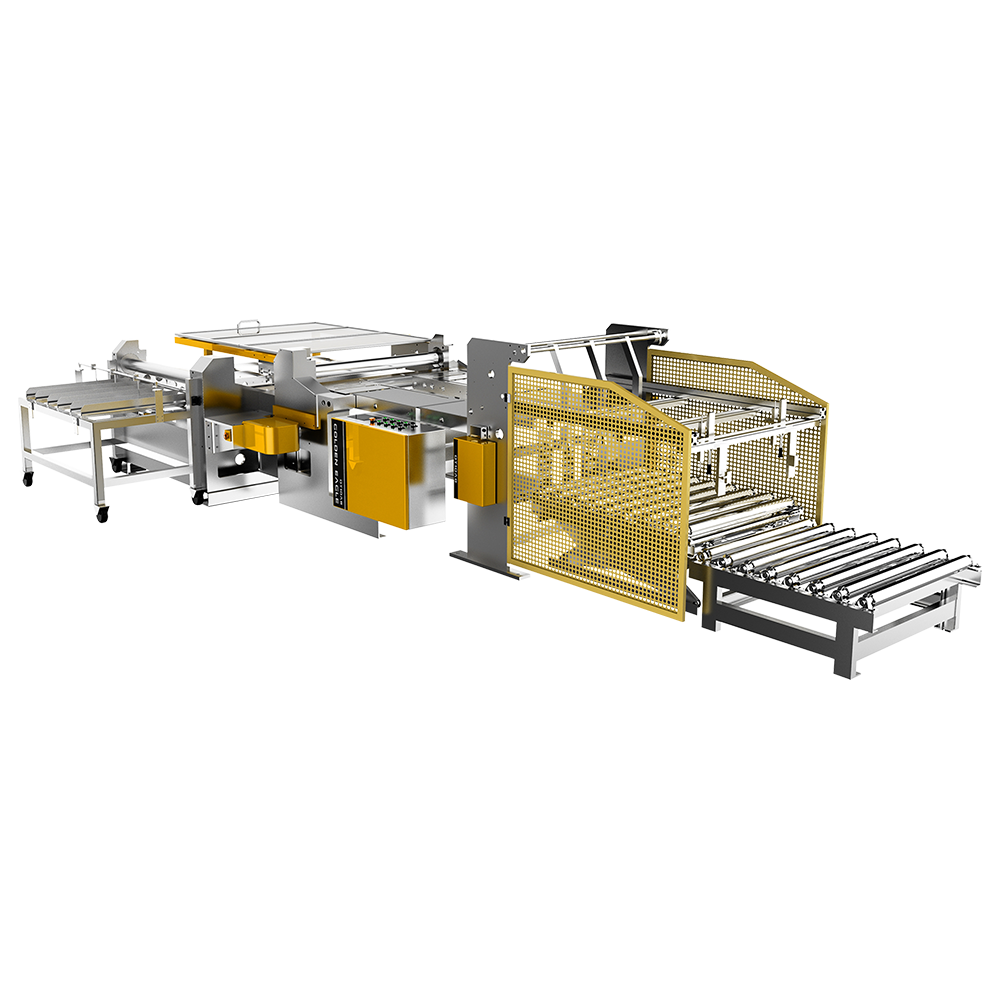

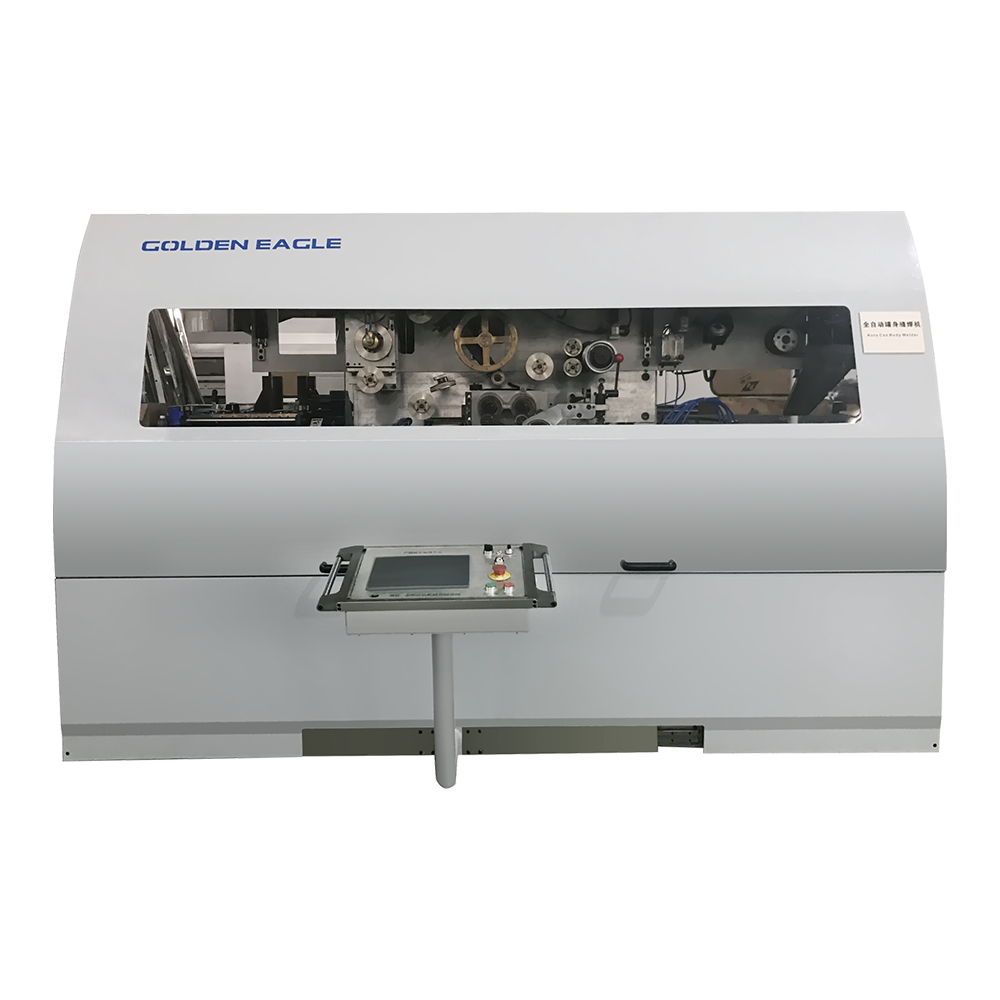

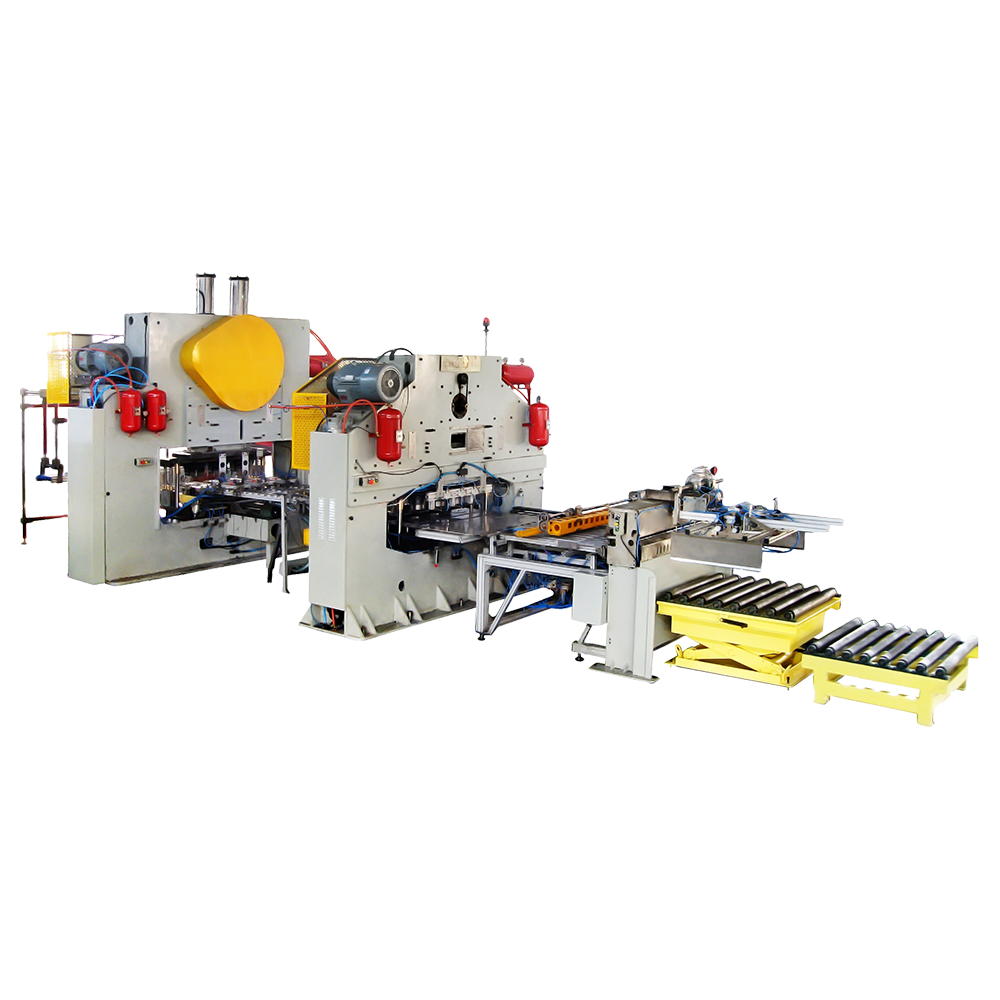

We have adopted advanced automation control systems and servo drive technology. These technologies enable machines to achieve high-speed and precise automated production processes, reducing manual intervention and waiting time. Meanwhile, the application of servo drive technology has also improved the dynamic response capability and positioning accuracy of the machine, further enhancing production efficiency and product quality.

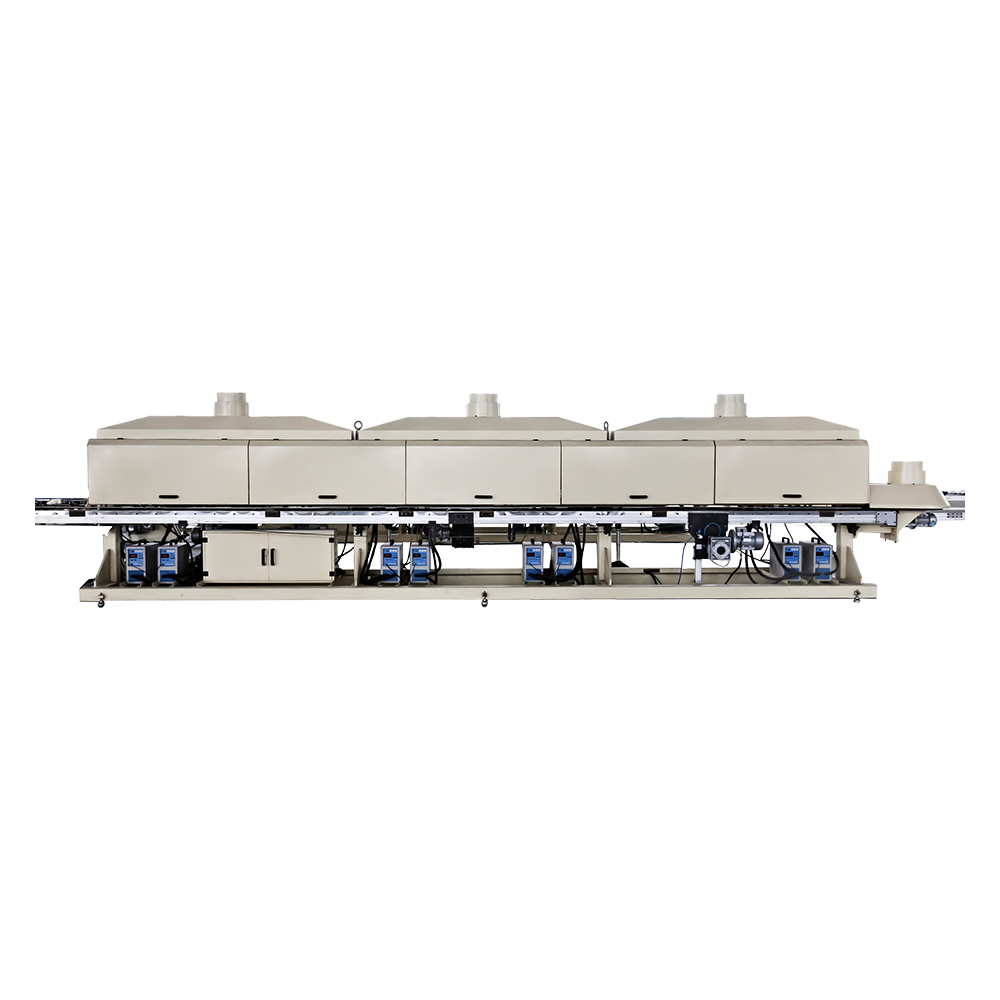

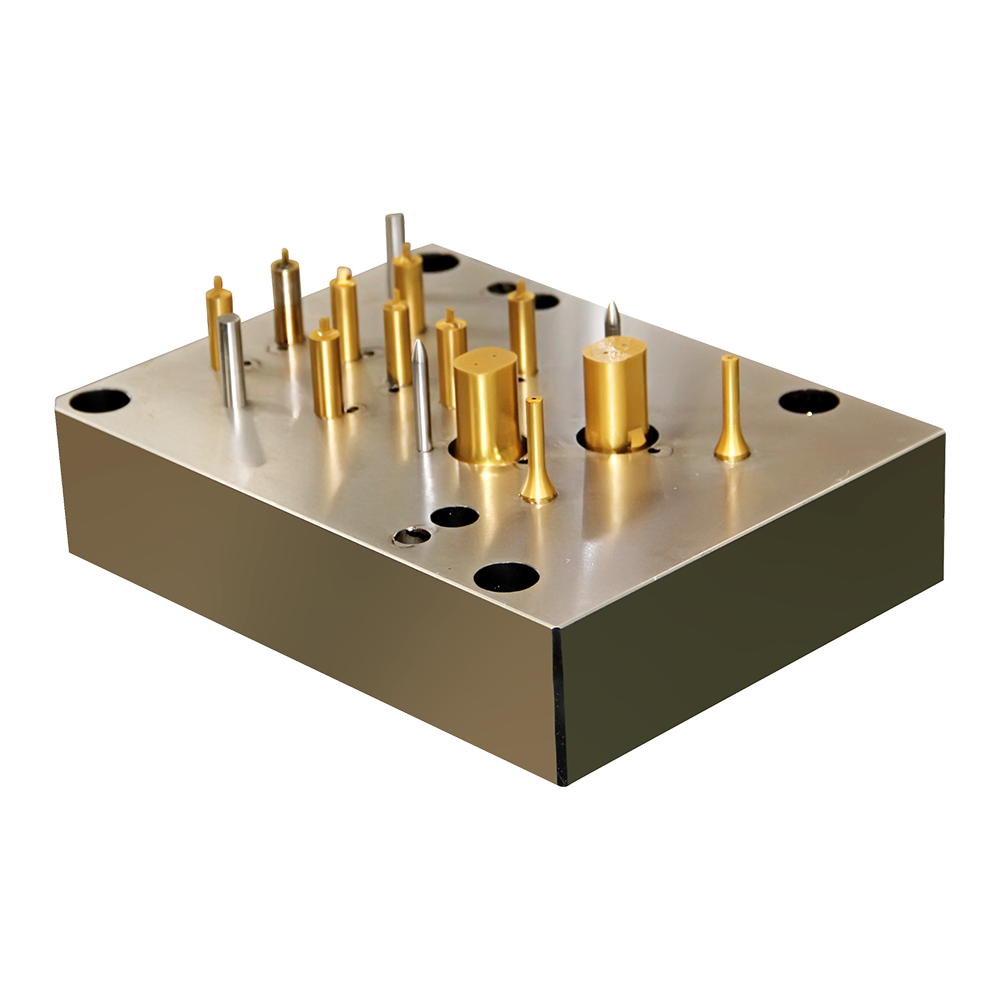

Secondly, we focus on optimizing the structure and improving the process of the machine. By using lightweight materials and optimizing structural design, we have reduced the overall weight and energy consumption of the machine. At the same time, we have conducted in-depth research and practice on production processes, and explored an efficient and low-cost production plan. For example, we have adopted continuous stamping and die-cutting technology to achieve rapid molding and cutting of can lids; We have also introduced an online detection and quality traceability system to ensure the stability and traceability of product quality.

In addition, we also focus on the application and promotion of intelligent technology. By introducing advanced technologies such as the Internet of Things, big data, and artificial intelligence, we can achieve real-time monitoring and data analysis of machine production processes. This not only helps to detect and solve production problems in a timely manner, but also provides customers with more accurate production forecasting and decision support. Meanwhile, the application of intelligent technology can also help us continuously optimize production processes and improve resource utilization efficiency, further reducing production costs and enhancing market competitiveness.