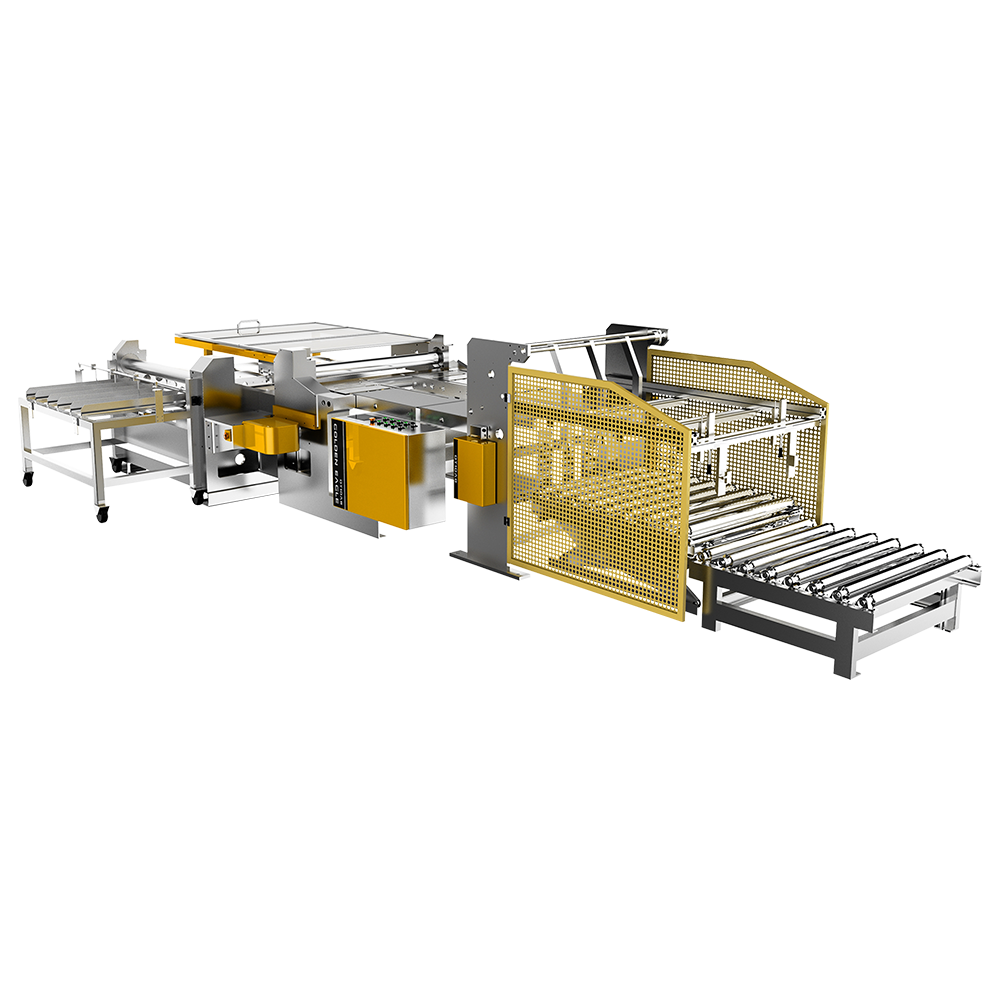

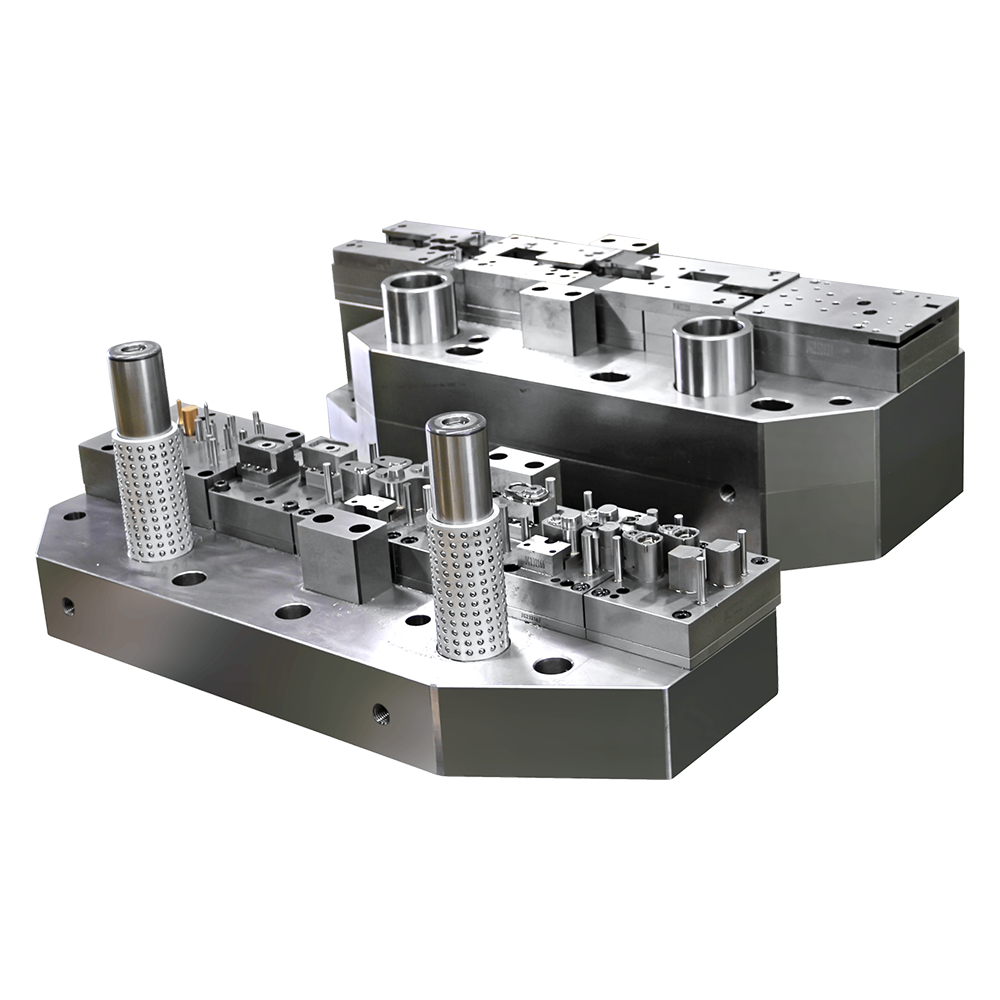

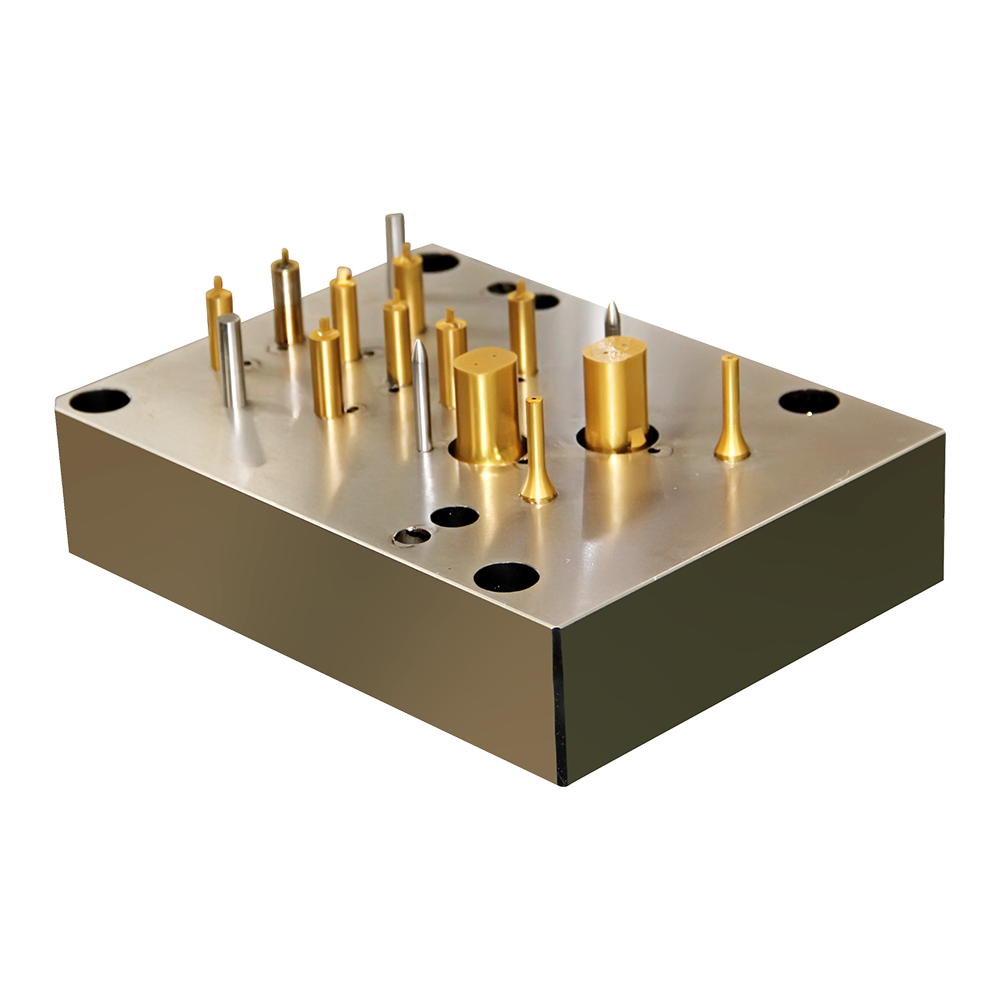

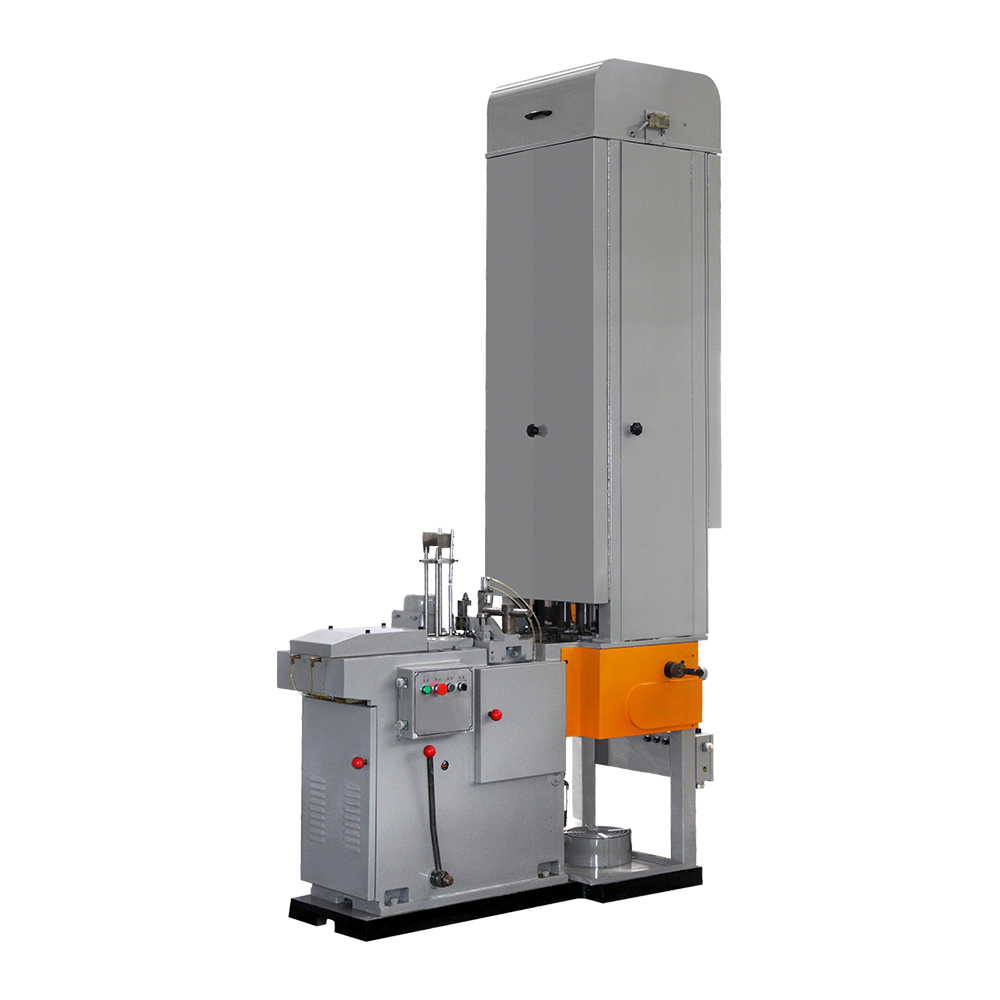

Ensuring high precision and consistency of the product is crucial in the design and manufacturing process of TIN CAN LID END MAKING MACHINE. This not only affects the quality and performance of the final product, but also directly impacts customer satisfaction and market competitiveness. To achieve this goal, we fully utilize advanced CAD/CAM technology for precise 3D modeling and simulation analysis during the design phase. By accurately calculating and optimizing design parameters such as mold structure, stamping path, material flow, etc., the machine is theoretically capable of high-precision production. At the same time, we will also customize the design of various parts of the machine according to the specific needs of customers to meet the production requirements of different specifications and shapes of can lids.

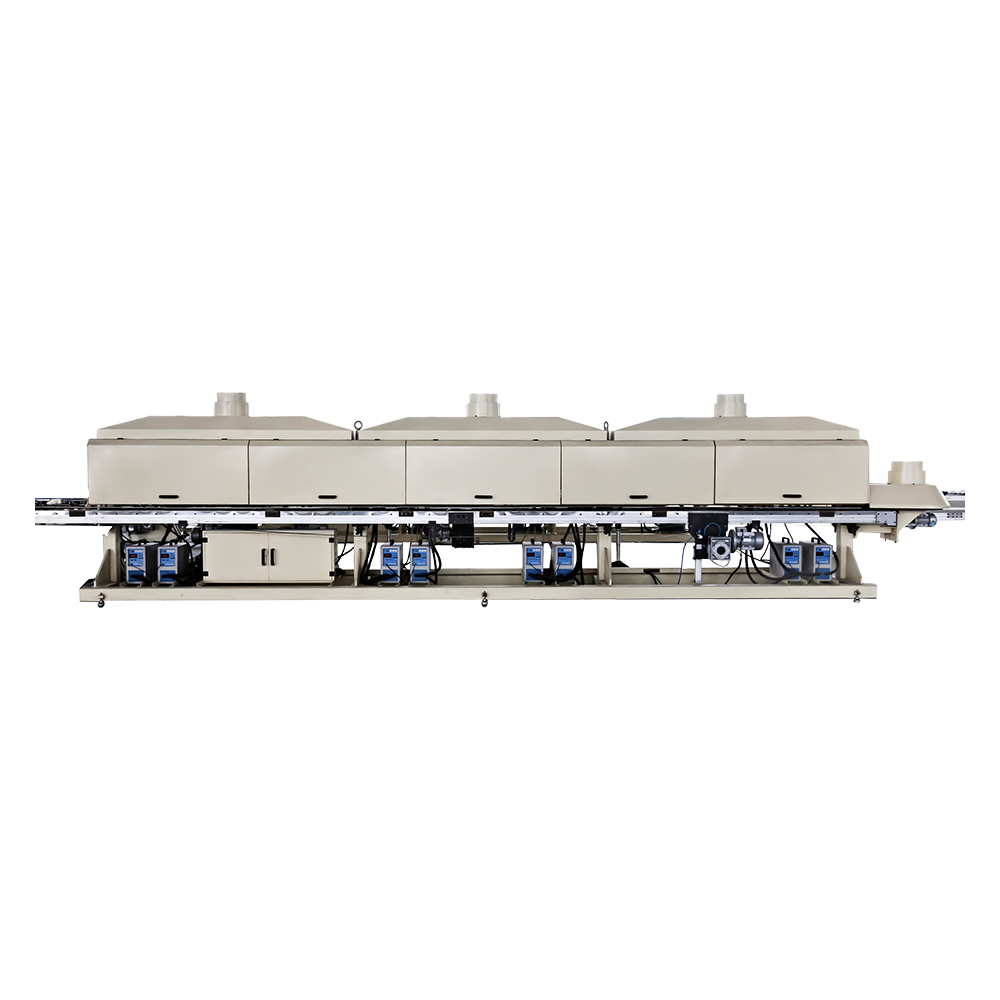

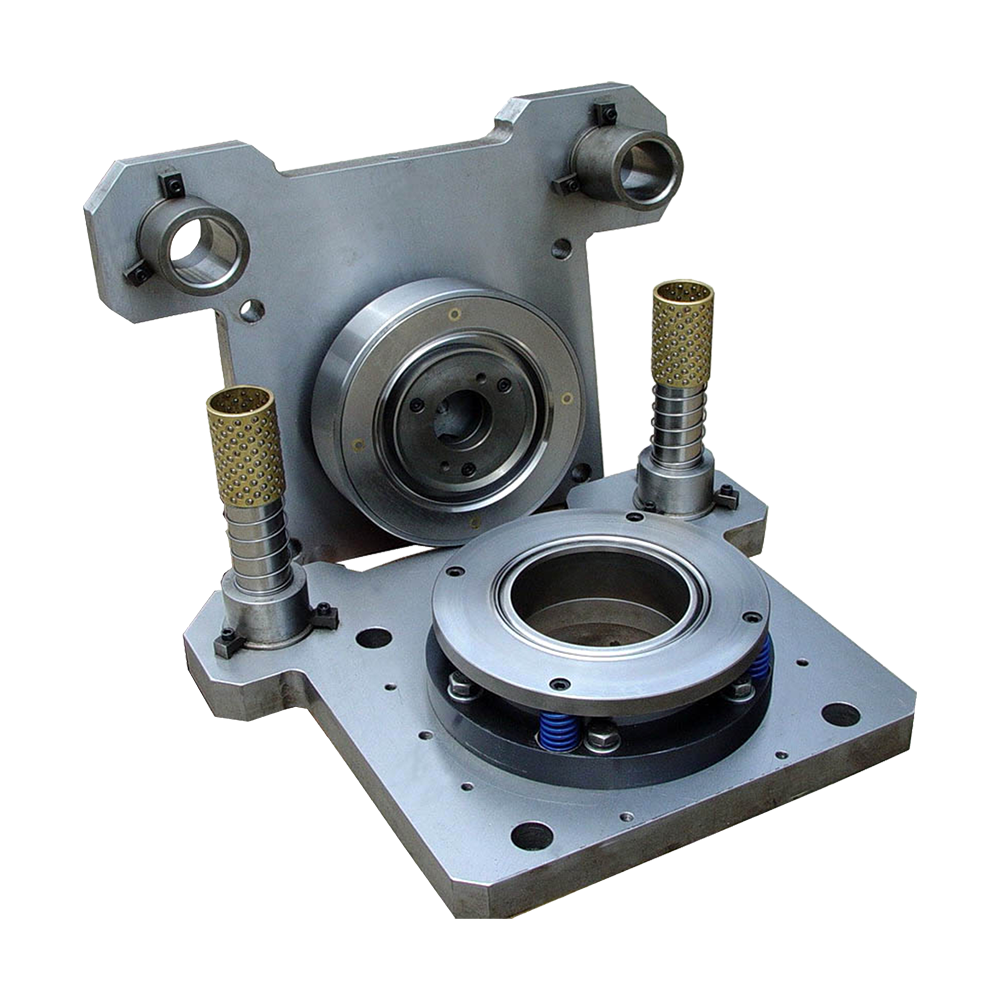

In the manufacturing stage, we strictly follow the ISO quality management system standards and carry out strict quality control for every link such as raw material procurement, production and processing, assembly and commissioning. Especially in mold manufacturing, we use high-precision CNC machining centers and advanced surface treatment technology to ensure the accuracy and durability of the molds. In addition, we will conduct multiple trial runs and debugging of the machine, continuously adjusting and optimizing process parameters to achieve optimal performance in actual production.

In the after-sales service stage, we will provide customers with comprehensive technical support and training services. This includes on-site installation and debugging, operation training, regular maintenance, and emergency troubleshooting. By establishing close cooperative relationships with customers, we can timely understand the usage of machines and continuously improve and optimize them based on feedback, thereby continuously enhancing the high precision and consistency of our products.