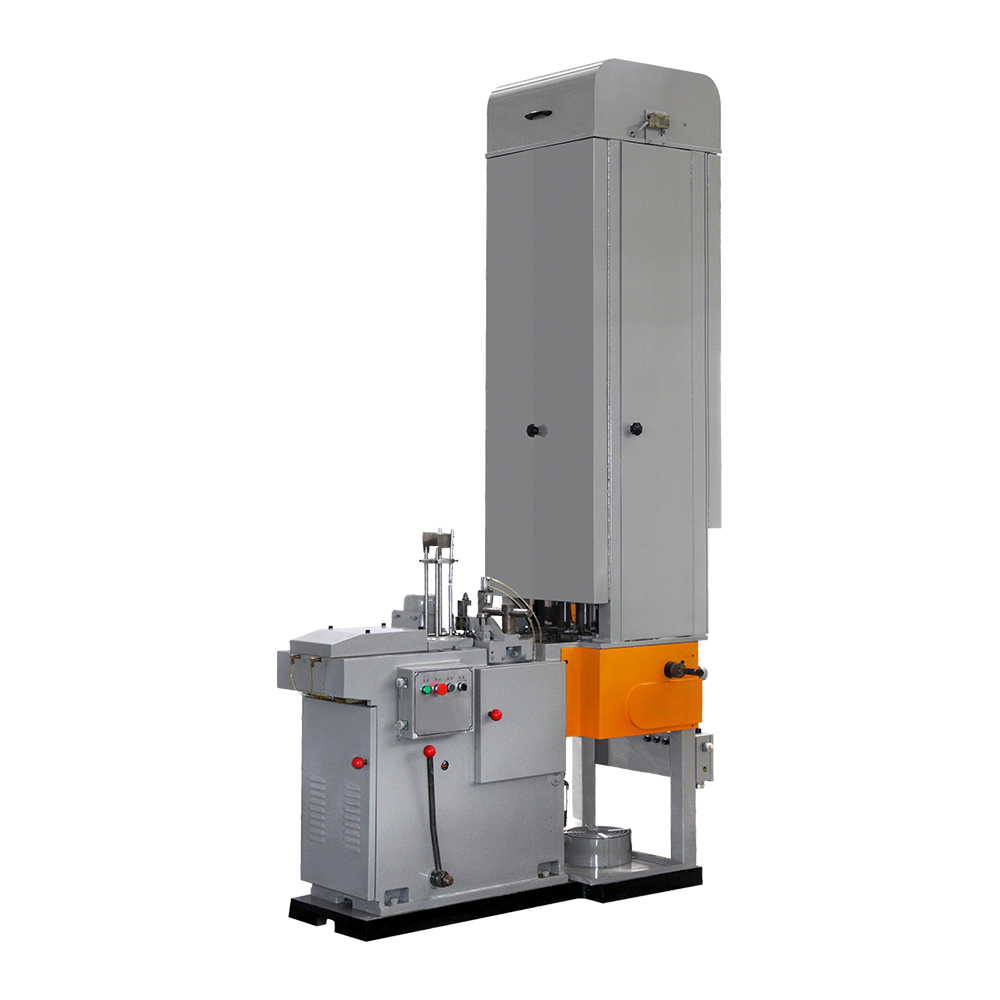

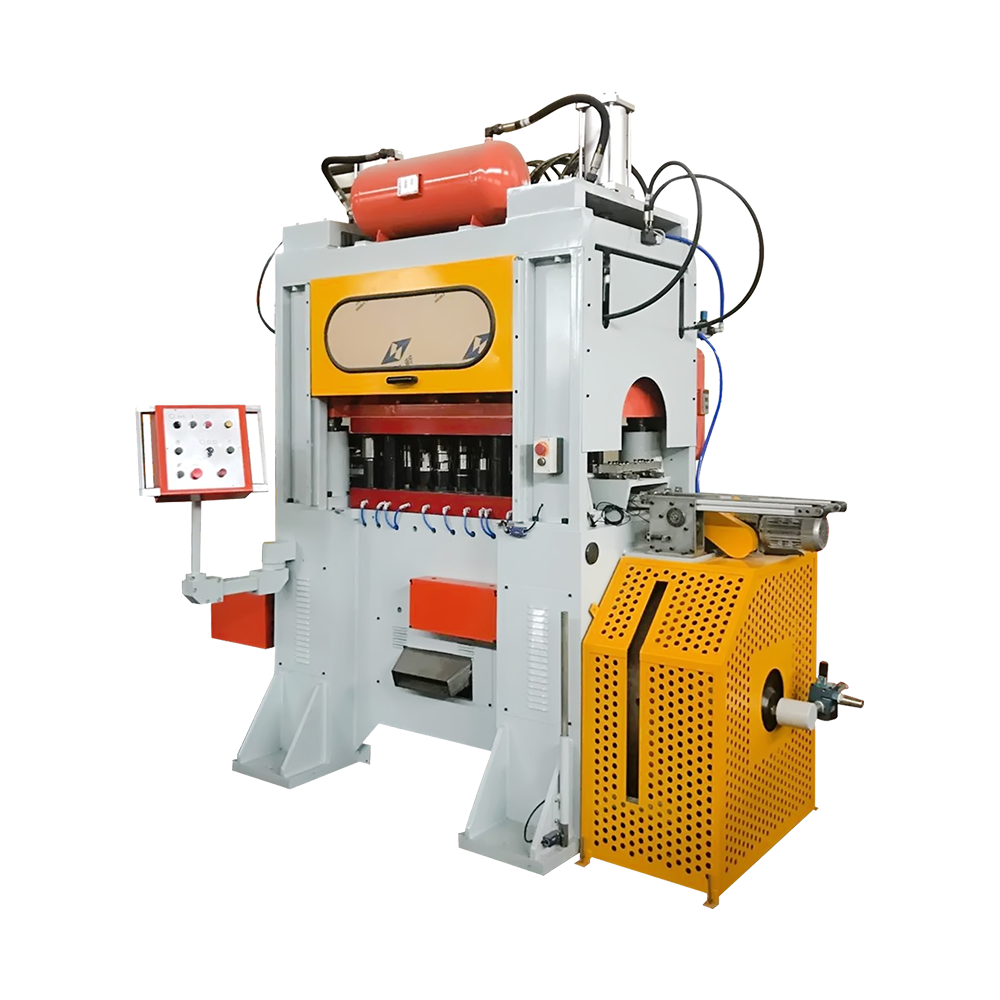

GT10A8 Automatic Compound Cutting Machine uses efficient cooling systems and heat management measures to deal with the heat generated during the cutting process to ensure the safety and stable performance of the equipment and materials. Its cooling system usually adopts liquid cooling or air cooling technology to dissipate heat in time through coolant or forced airflow to prevent overheating of equipment and materials. The liquid cooling system removes heat through the circulation of coolant, while the air cooling system removes heat by blowing the cutting point through airflow. The equipment is equipped with temperature sensors inside to monitor the temperature of key components in real time. If the temperature exceeds the set range, the system will automatically adjust the cooling intensity or issue an alarm to prevent equipment damage.

In addition, GT10A8 may also be equipped with auxiliary cooling devices, such as a spray cooling system that sprays coolant during the cutting process to further reduce the temperature, or a compressed air cooling system that blows compressed air directly to the cutting point to quickly remove heat. The overall design of the equipment takes heat dissipation into consideration, and components such as heat sinks, thermal conductive materials, and high-efficiency heat dissipation fans are used to ensure that internal heat is quickly dissipated. The shell and internal structure of the equipment are optimized to maximize heat dissipation efficiency and prevent heat accumulation.

Through these designs and measures, the GT10A8 Automatic Compound Cutting Machine can effectively manage and process the heat generated during the cutting process, ensuring that the equipment and materials operate under efficient and safe conditions. The presence of the cooling system not only improves the service life of the equipment, but also ensures cutting accuracy and material quality.