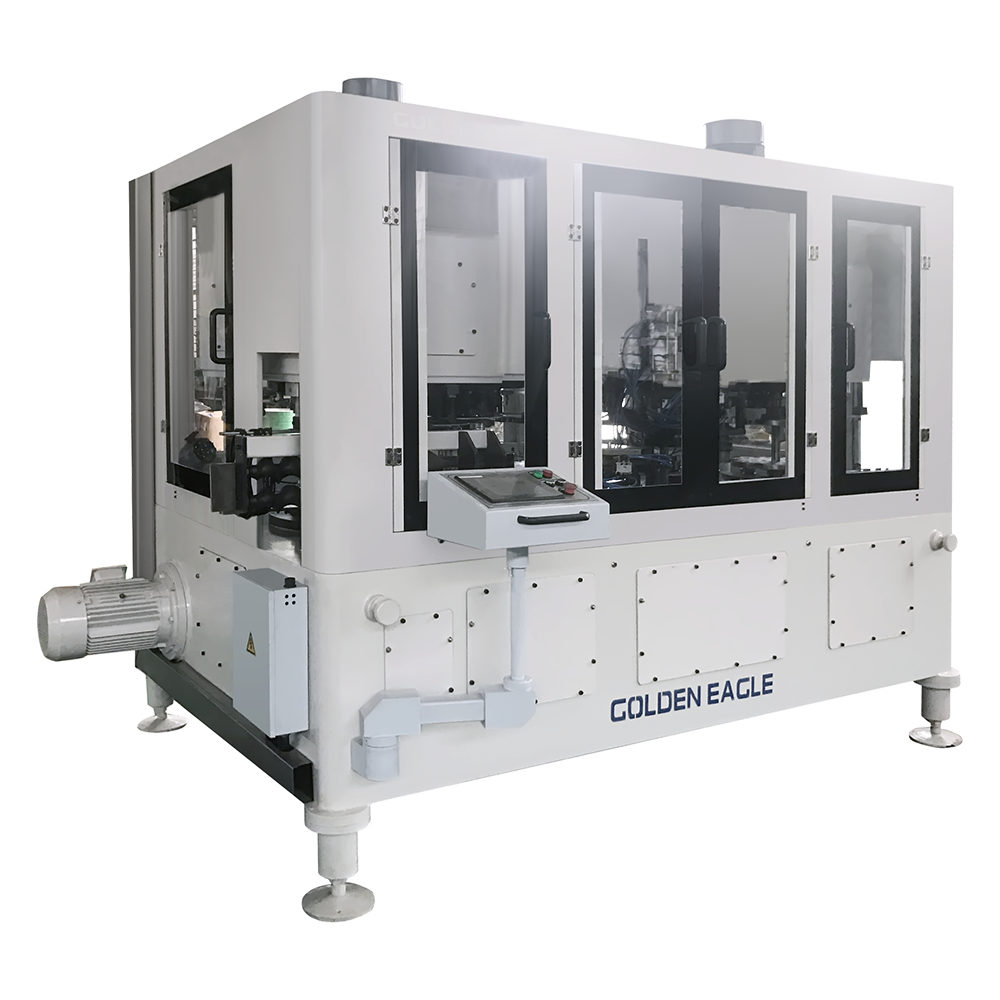

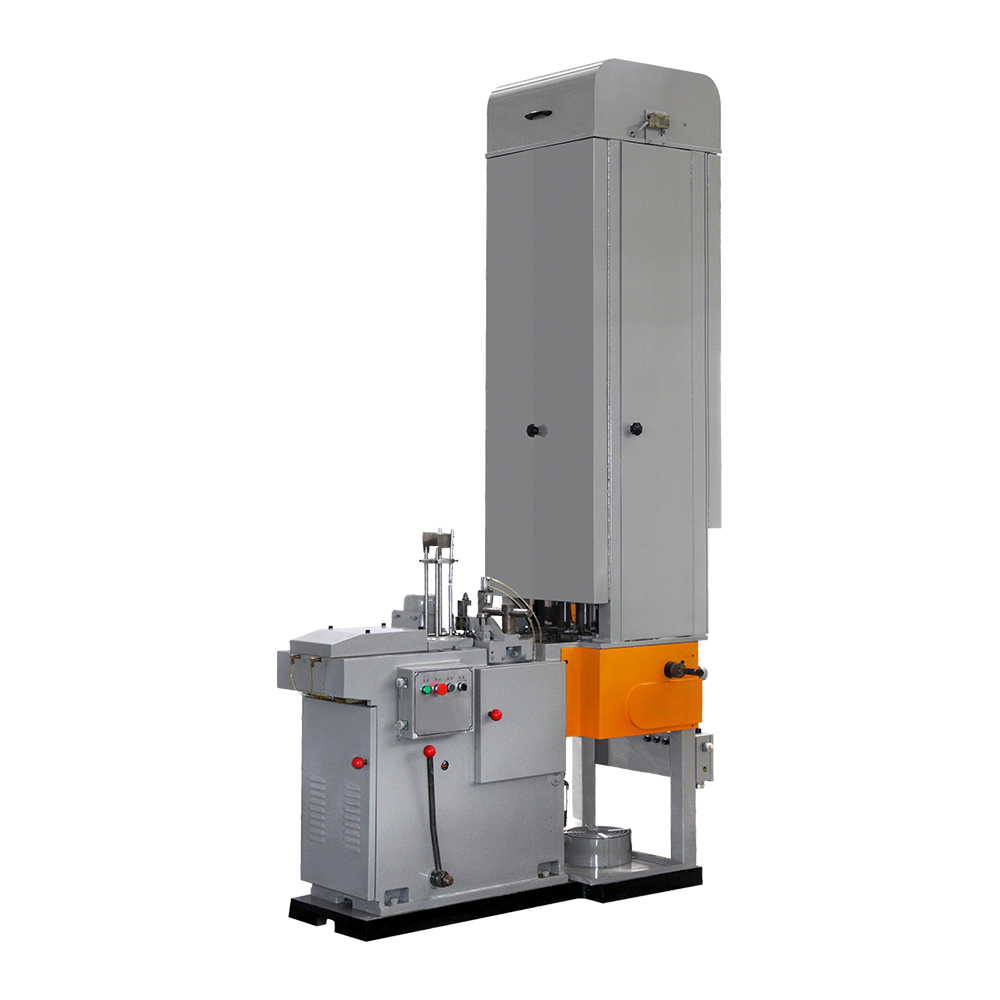

MILK POWDER CAN MAKING MACHINE is one of the indispensable key equipment in the modern food packaging industry. It ensures that the produced milk powder cans meet the precise standards in size and shape through multiple precise control and technical means.

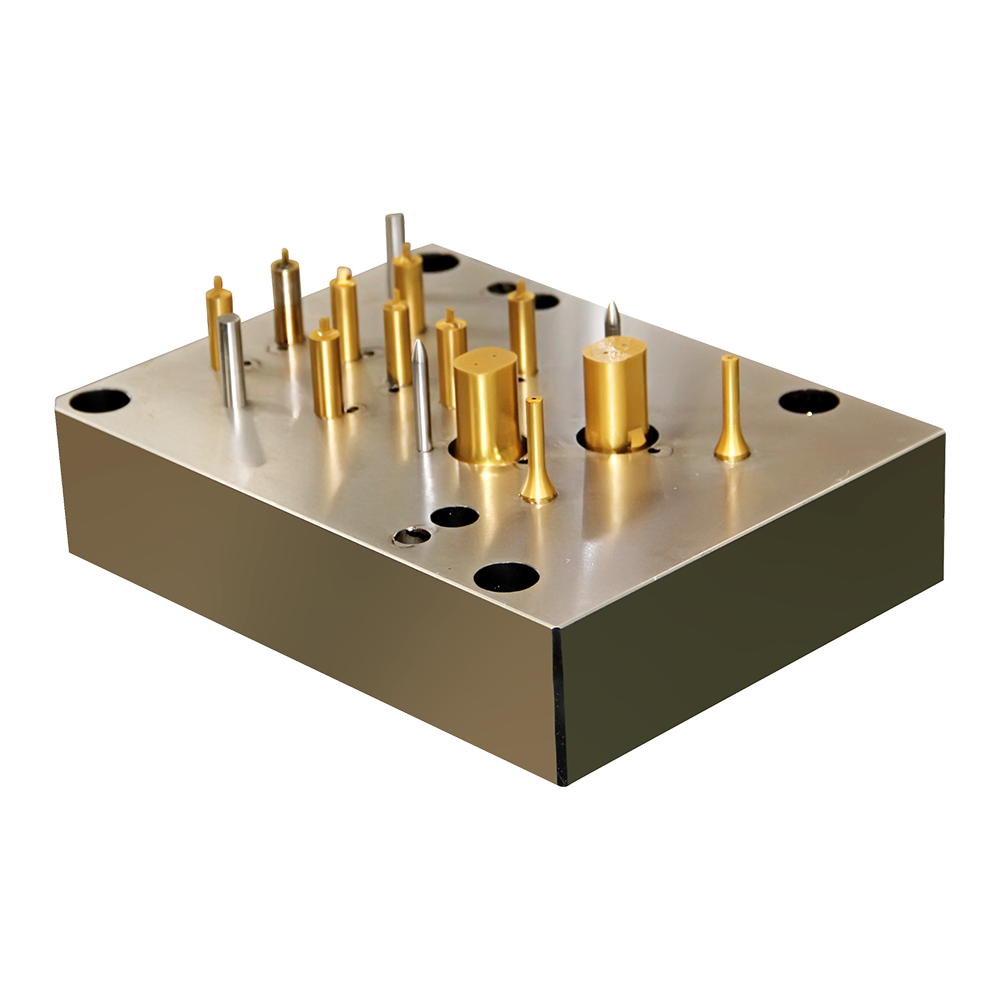

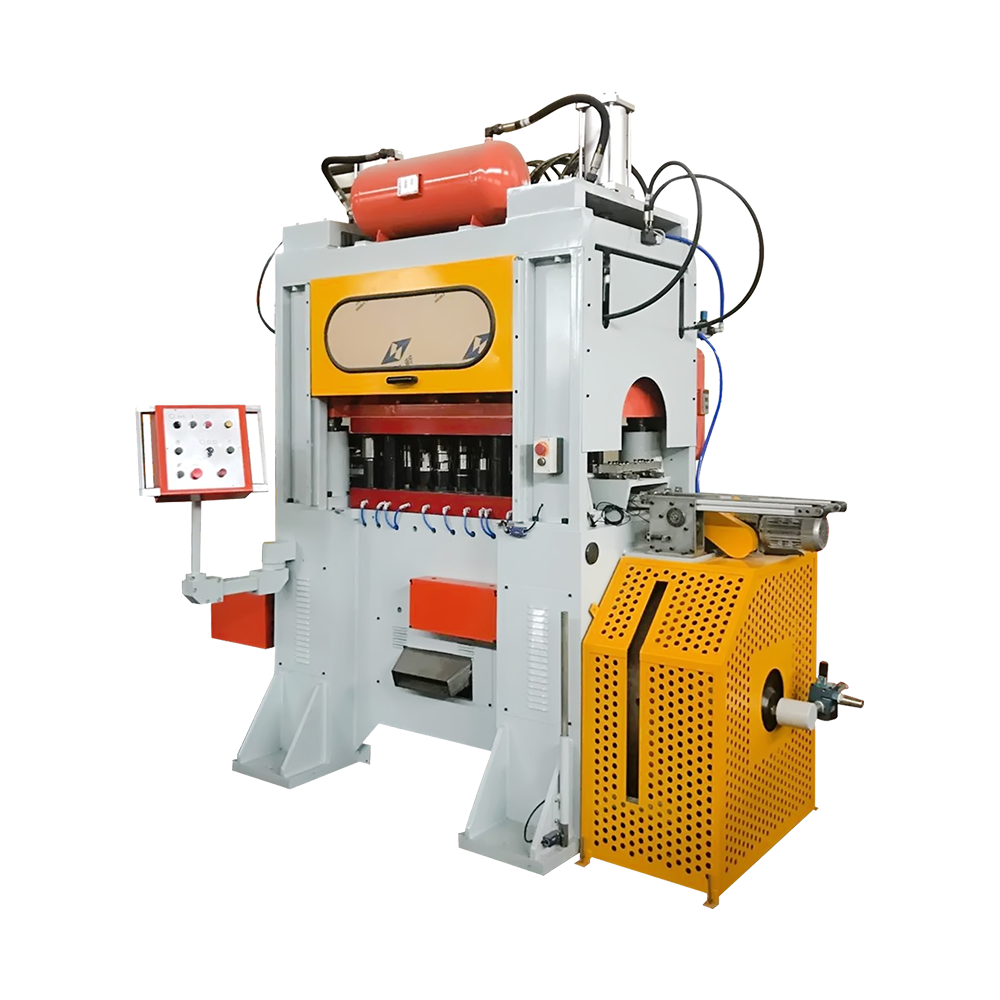

The key to the equipment lies in precise mold design and manufacturing. The mold is the main factor that determines the size and shape of the can body, and it must be accurate to every detail. The professional design team uses advanced computer-aided design (CAD) software to convert customer needs into precise mold design. The latest CNC machine tool (CNC) technology is used in the manufacturing process to ensure the manufacturing accuracy and stability of each mold. The selected materials have excellent mechanical properties and wear resistance, and can maintain the shape and size of the mold for a long time.

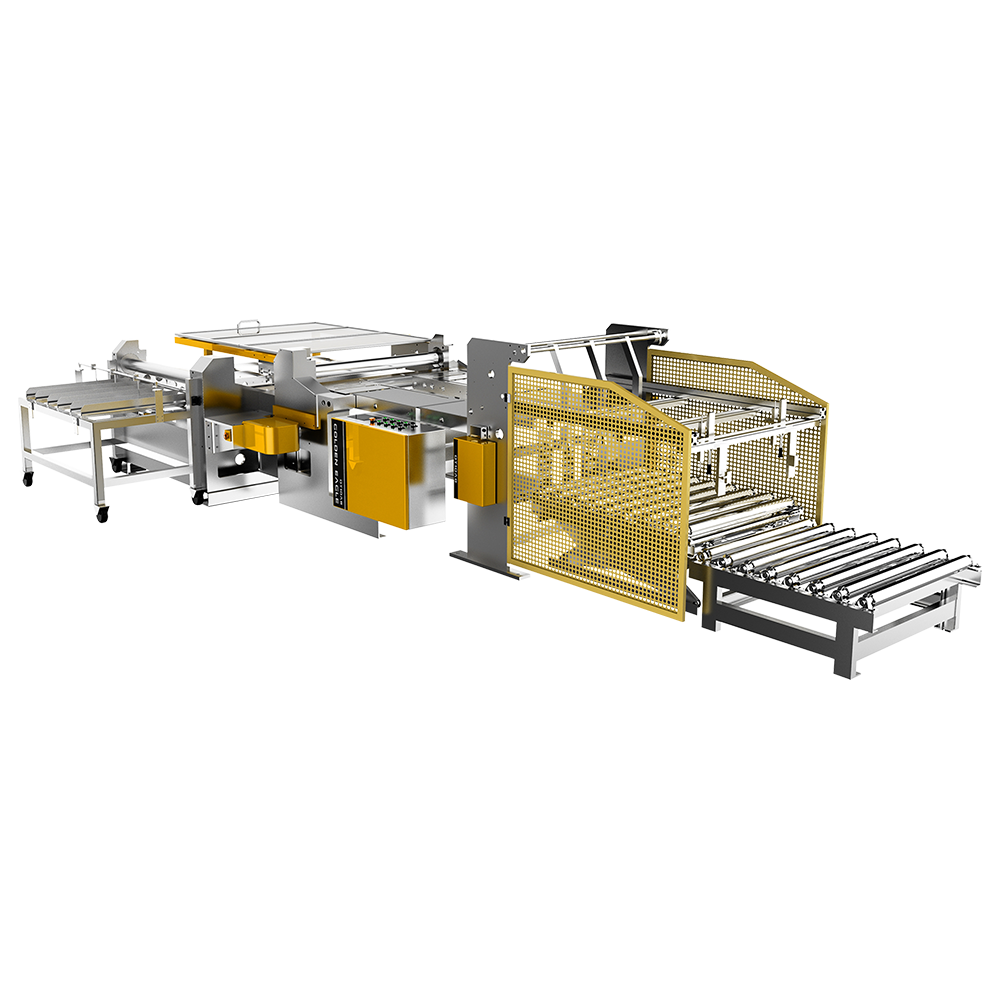

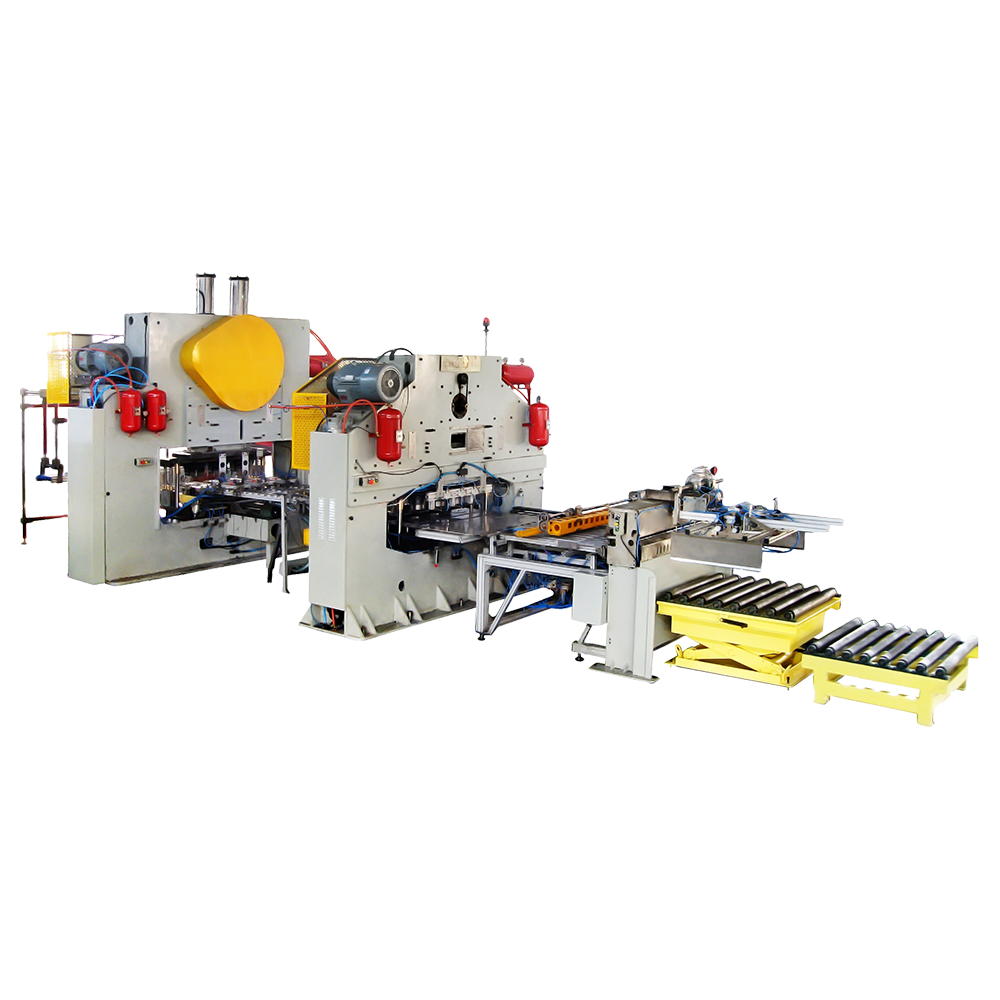

Modern milk powder can manufacturing machines are equipped with advanced automatic control systems that can monitor and adjust key process parameters in the production process in real time. By accurately controlling parameters such as pressure, temperature and speed, the can body size is ensured to remain consistent within each production cycle. The automation system greatly reduces the interference of human operation and improves production efficiency and product quality stability.

In addition, the automated production process of the machine enables it to quickly adapt to the production needs of milk powder cans of different specifications and capacities. After professional training, operators can flexibly adjust the equipment's working settings and production processes to meet customers' personalized requirements. The equipment design takes into account the diversity of production environments and can operate stably in different production sites and climatic conditions.