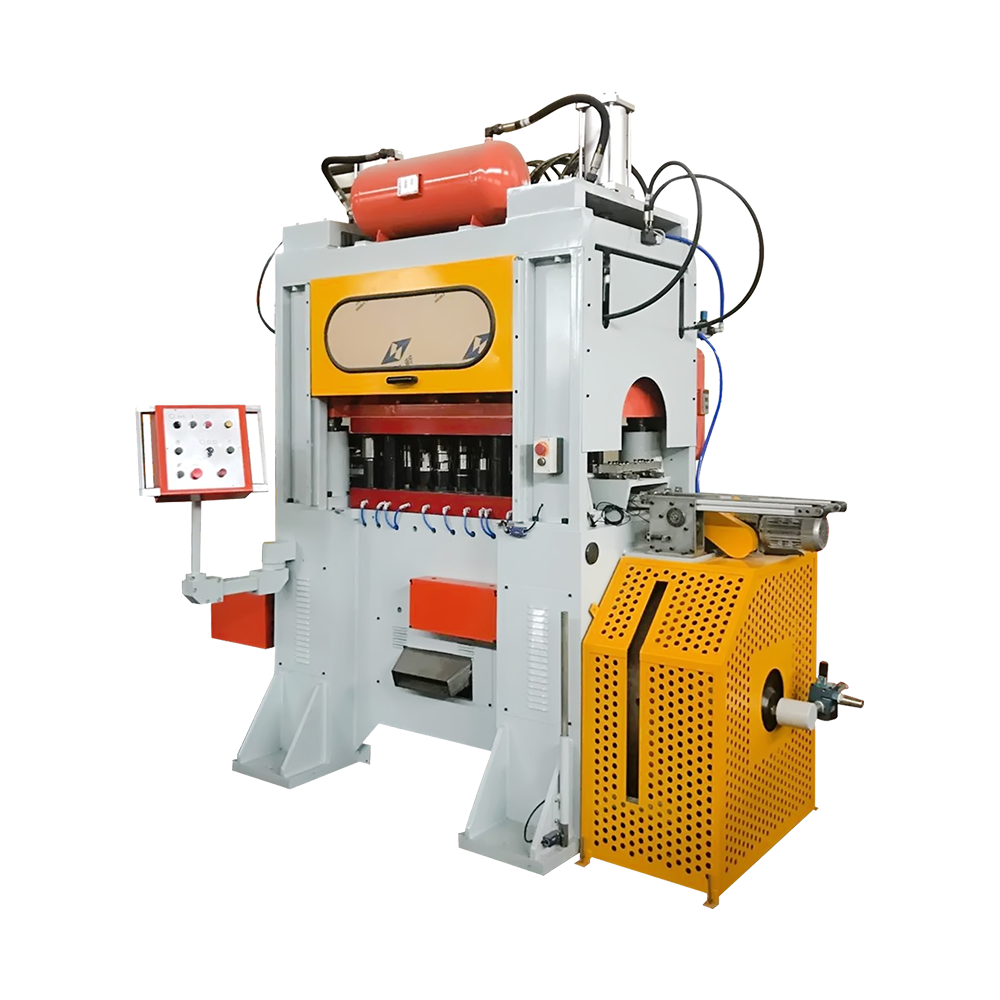

The chemical tank making machine ensures precision and uniformity in the shape and size of the tanks through a combination of advanced design, precise control systems, and high-quality components. These machines are equipped with automated processes that carefully monitor and adjust various factors during production to maintain consistent tank dimensions and quality.

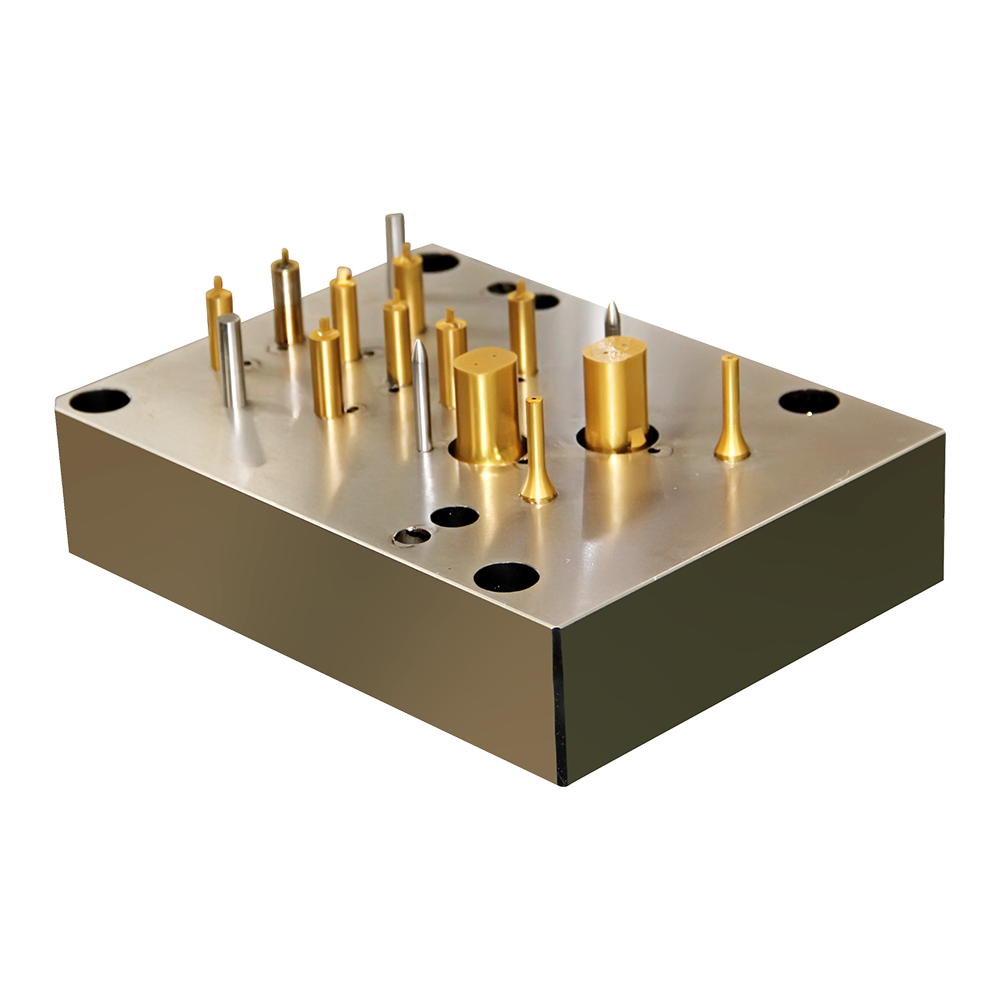

One of the primary ways precision is achieved is through the use of precise molds and formers that are custom-designed for the specific tank requirements. These molds are crafted to exact specifications, ensuring that the shape and size of each tank produced are consistent. The machines apply controlled pressure and temperature to the molds to form the tanks, preventing any deformities or size inconsistencies. By controlling the molding process, the machine can create uniform tanks in terms of both shape and thickness, which is critical for ensuring their structural integrity.

Additionally, chemical tank making machines are often equipped with automated feedback systems that monitor the production process in real-time. These systems use sensors and cameras to check for variations in tank size or shape during production. If any irregularities are detected, the machine can automatically adjust the molding or forming parameters to correct the issue, ensuring that each tank meets the required specifications.

The precision of the machine is also supported by advanced control mechanisms that regulate factors like temperature, speed, and pressure during the production cycle. By maintaining these variables within tight tolerances, the machine ensures that each tank is molded accurately and consistently, without defects or variations that could affect the tank's performance.

Finally, some chemical tank making machines incorporate multi-stage processes, where each step of production is monitored and controlled separately. This approach allows for finer adjustments to be made at each stage of the manufacturing process, further enhancing the precision and uniformity of the tanks. Whether it's during the initial molding, cooling, or finishing stages, every step is optimized to ensure the final product meets the desired specifications for size, shape, and durability.

By combining advanced molding technology, real-time monitoring, and precise control systems, a chemical tank making machine can produce tanks with high levels of accuracy and uniformity, ensuring that each tank is reliable and meets industry standards for quality.