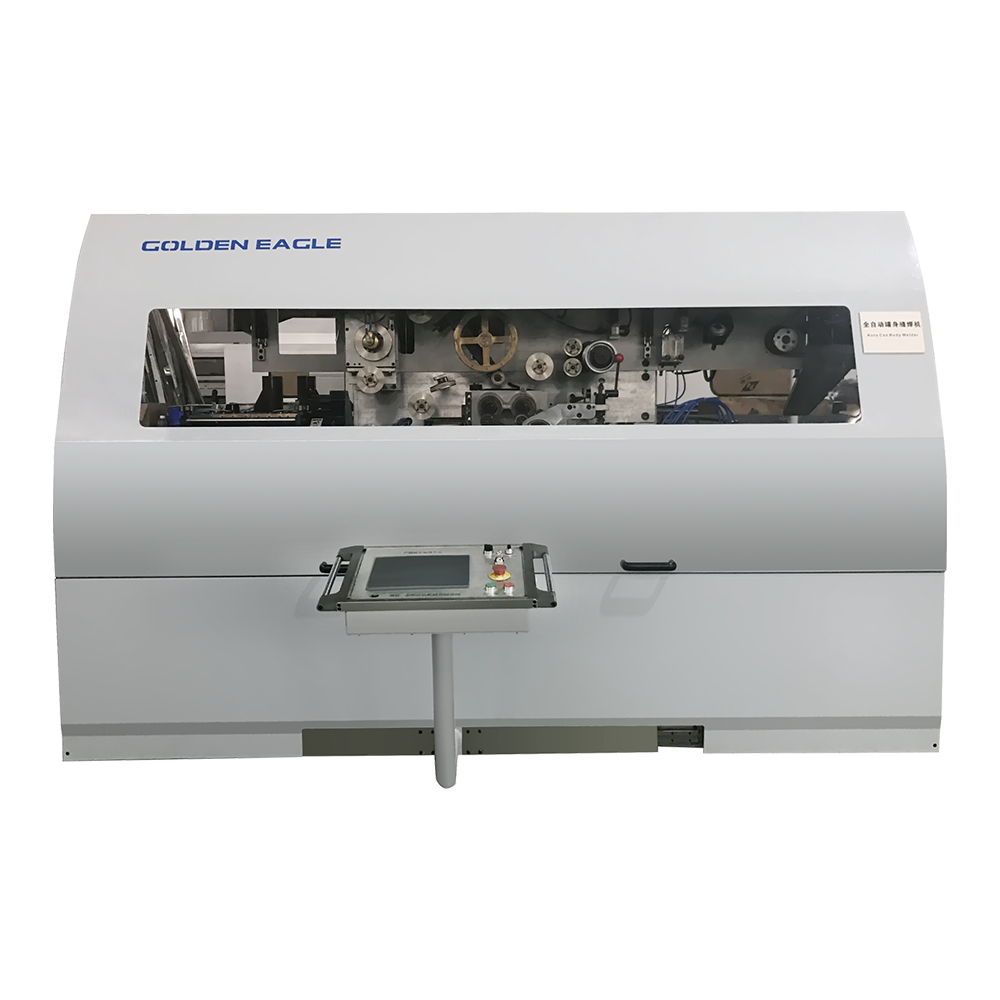

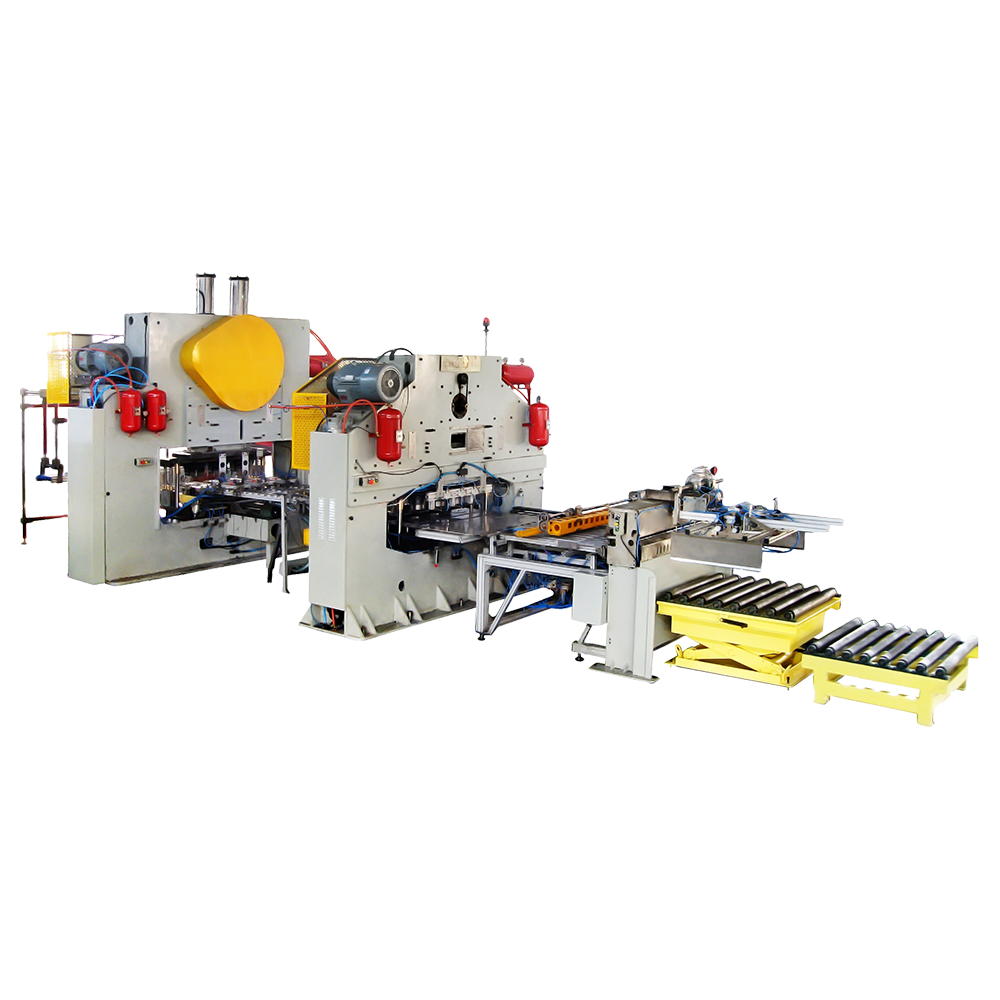

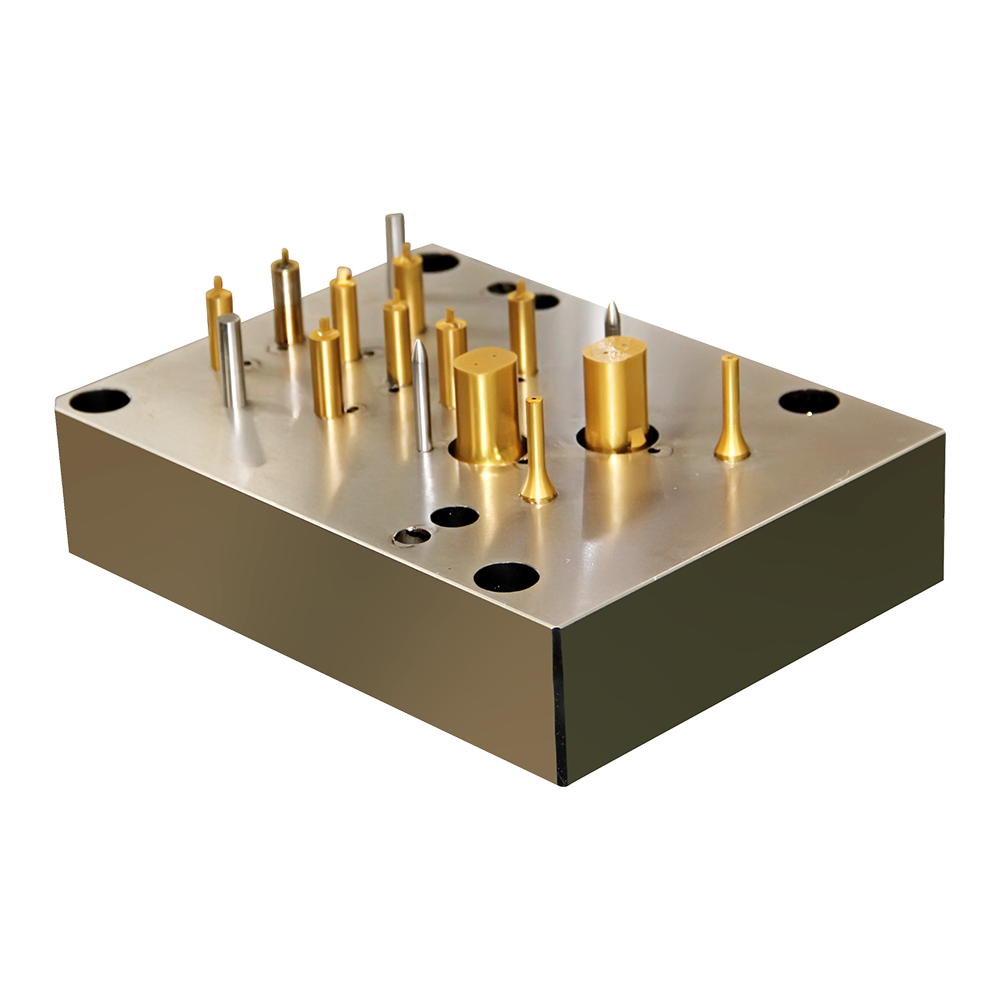

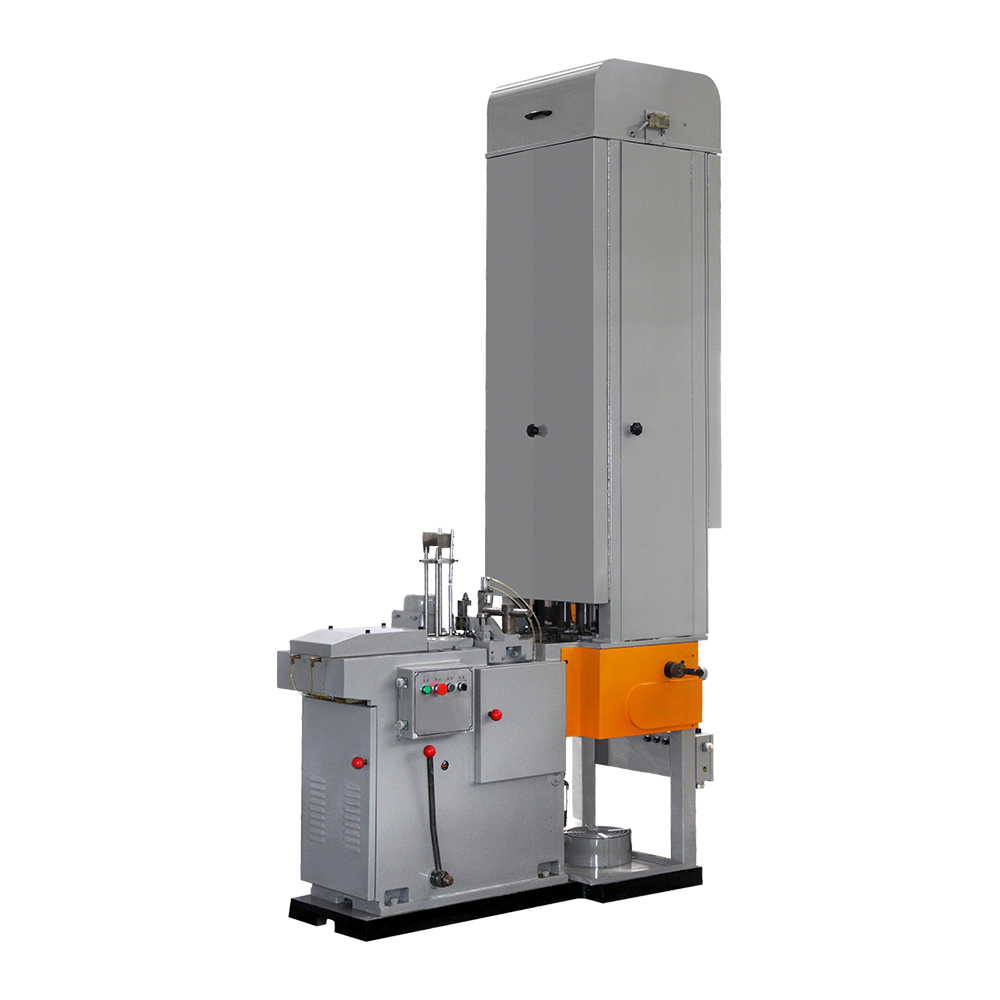

For consumers, to determine whether the aerosol cans produced by AEROSOL CAN MAKING MACHINE are safe and reliable, they can consider the following aspects, such as the material and production process of the aerosol cans. High quality aerosol cans are usually made of high-quality metal sheets or special alloy materials, and undergo strict surface treatment processes such as cleaning, phosphating, and spraying to improve their corrosion resistance and aesthetics. At the same time, the progressiveness and stability of production process are also important factors to judge the quality of aerosol cans.

A well sealed aerosol can can ensure that the product maintains stable air pressure and effective ingredients do not leak during use. Aerosol cans with strong pressure resistance can withstand certain pressure changes during transportation, storage, and use without deformation or rupture. Consumers can evaluate the sealing and pressure resistance of aerosol cans by observing their sealing structure, checking for leaks, and understanding the product's pressure rating.

In addition, consumers can also pay attention to the environmental friendliness and safety of the product. In terms of environmental protection, it can be checked whether the aerosol can is made of recyclable or biodegradable materials; In terms of safety, it can be understood whether the product has passed relevant safety certifications and tests, such as UN certification, CE certification, etc. These certifications and tests ensure that aerosol cans meet safety standards and environmental requirements during production and use.

Consumers can also judge the quality of aerosol cans through user experience and feedback. High quality aerosol cans should be able to maintain a stable spray effect, free of leakage, and easy to open and close during use. Meanwhile, consumers can also pay attention to the reviews and feedback from other users to understand the actual usage and reputation of the product.