Noise control design for chemical tank making machines is an important consideration, especially during production, where noise may have an adverse effect on the working environment and the health of employees. Without effective noise control measures, the noise generated during equipment operation may exceed safety limits, causing damage to hearing from long-term exposure and affecting employee work efficiency and comfort.

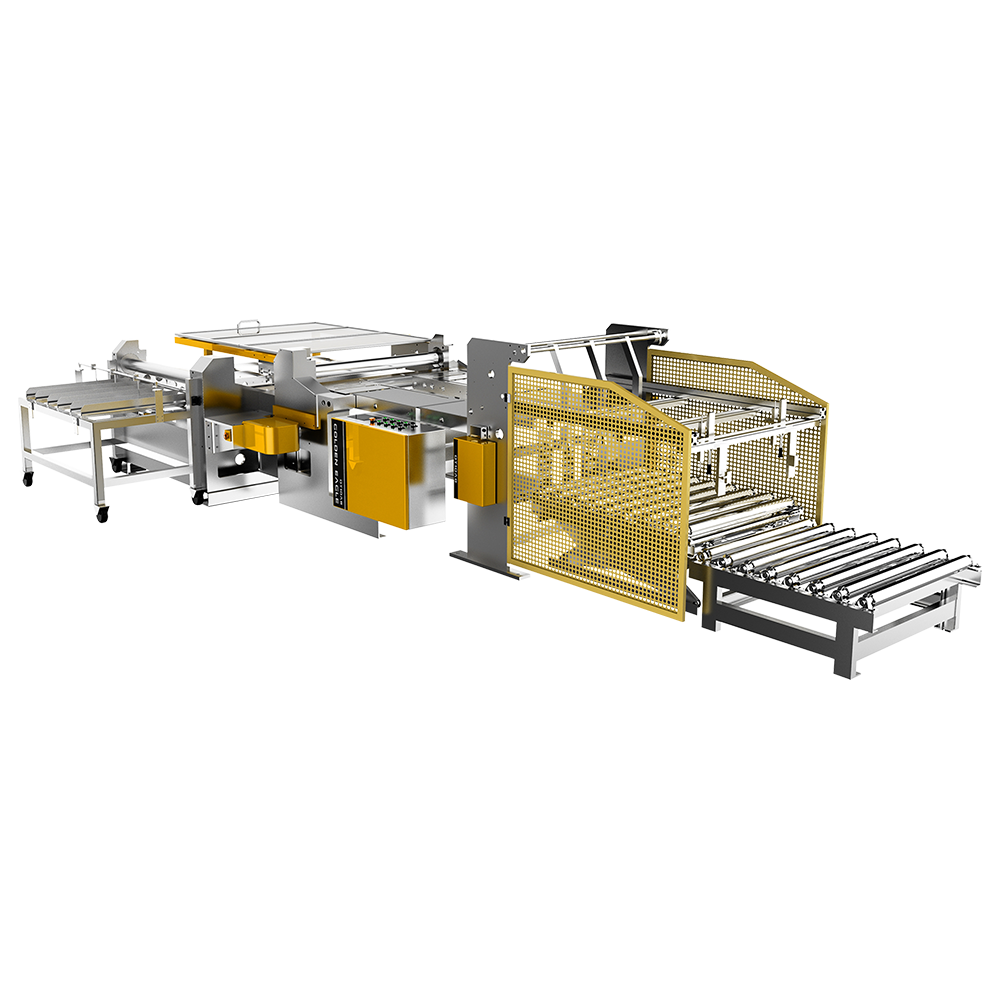

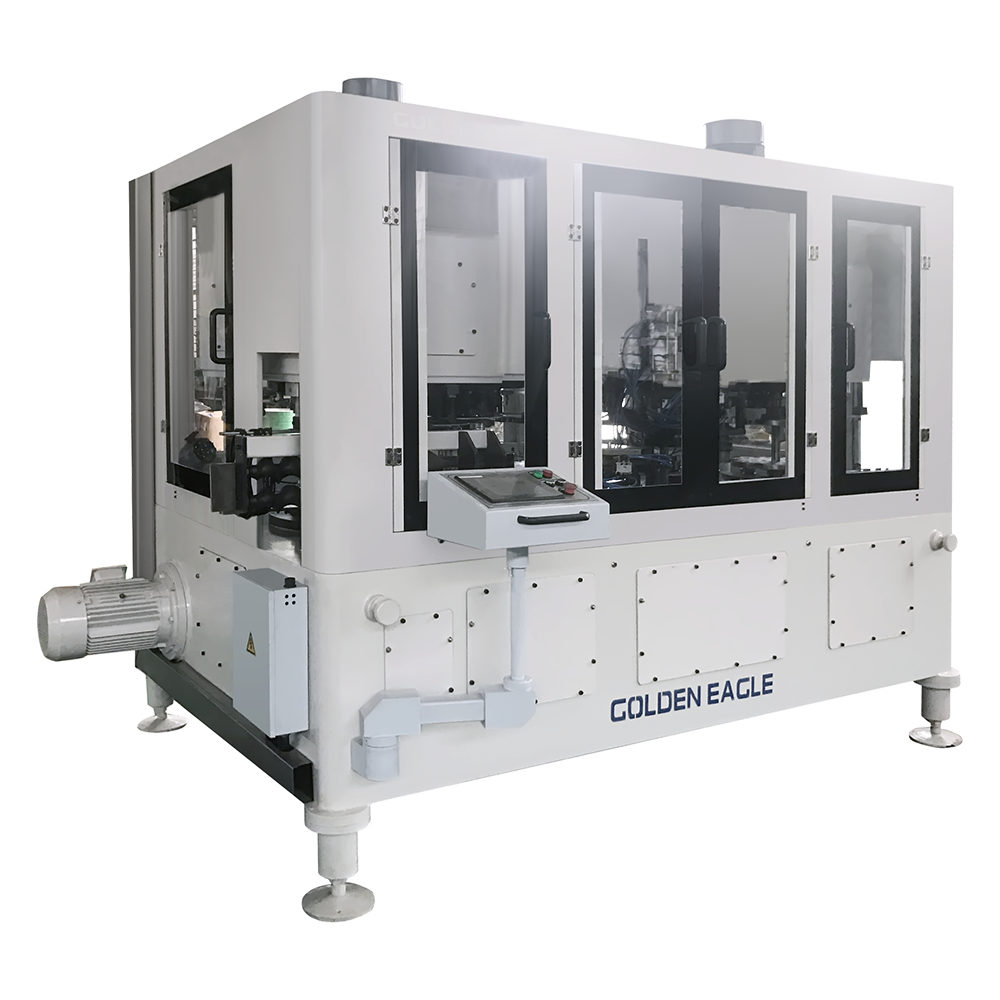

Modern chemical tank making machines often use a variety of noise control technologies to reduce noise generation. Common designs include thickening the body shell, installing sound insulation materials, and using low-noise motors or drive systems. These measures can effectively absorb and isolate the sound generated during machine operation, prevent noise from spreading to the surrounding environment, and reduce the impact on the factory environment.

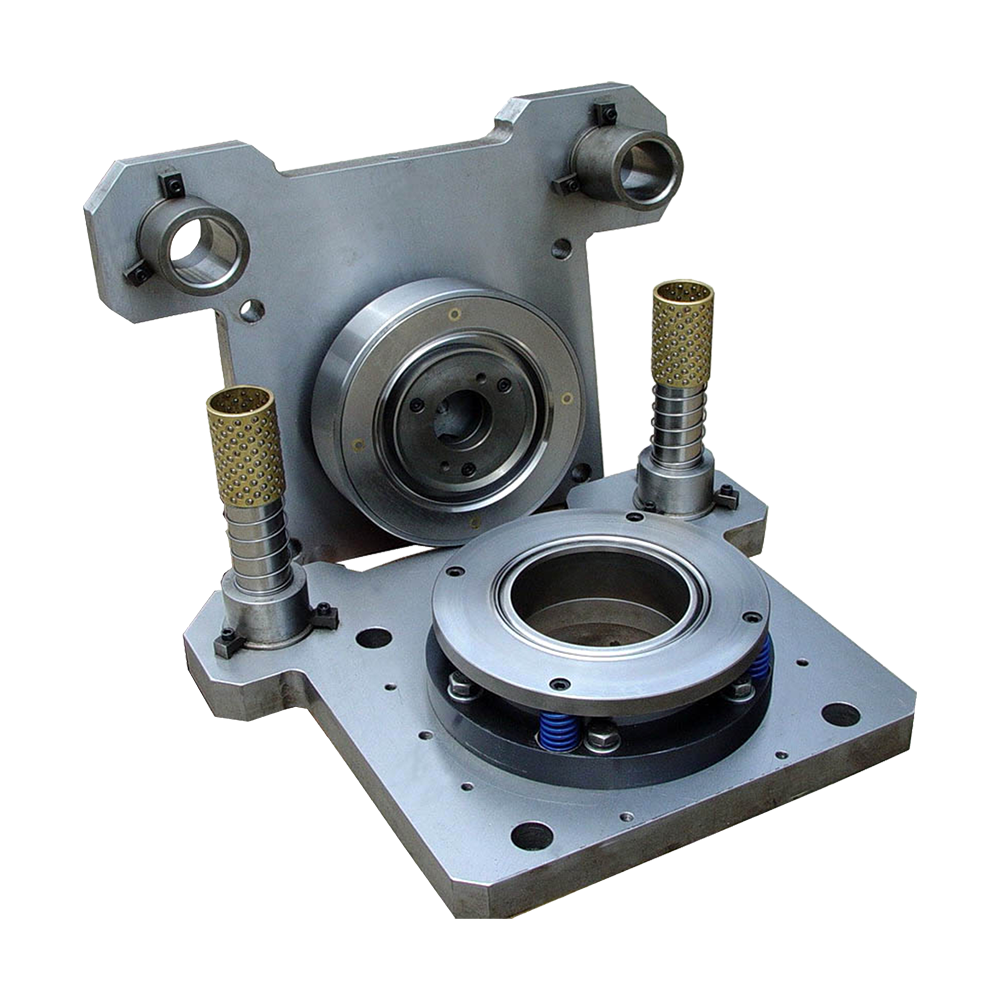

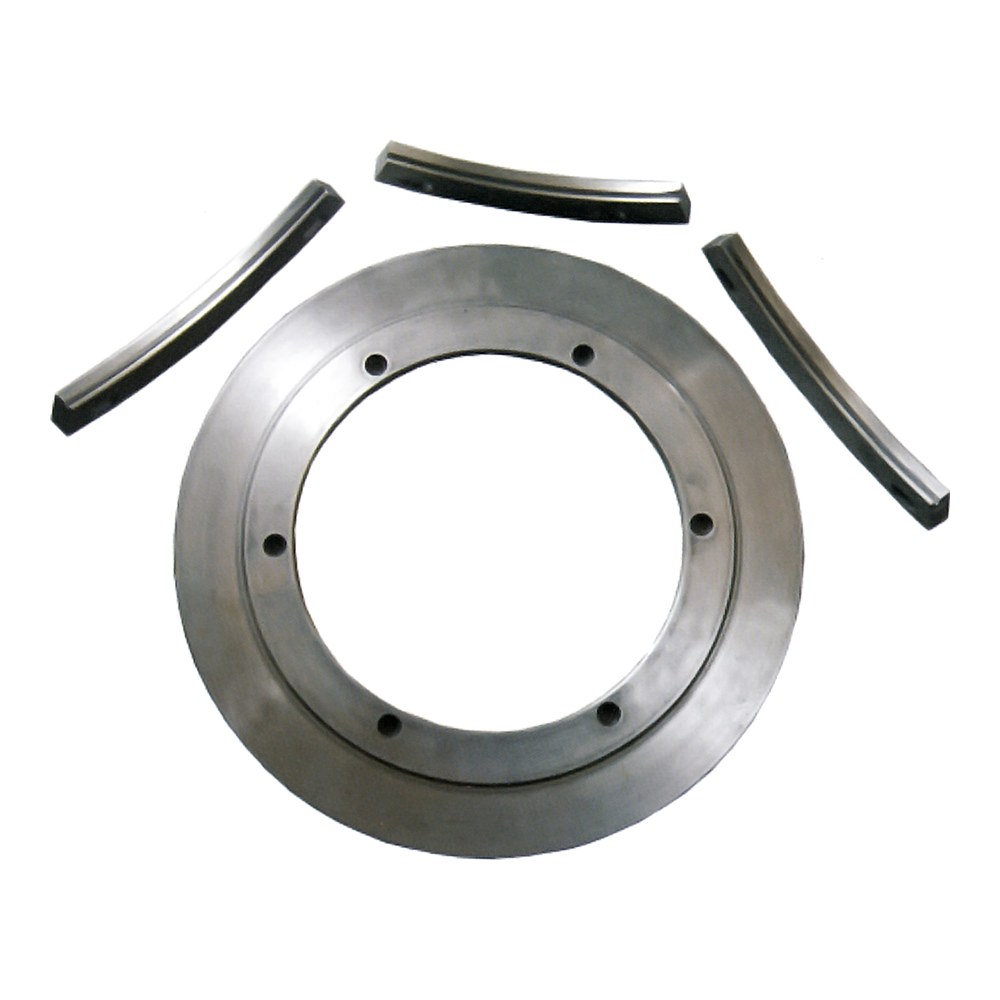

Vibration and mechanical shock inside the equipment are also one of the main sources of noise generation. To reduce this noise, many chemical tank making machines are equipped with vibration mitigation systems, such as installing shock pads, spring brackets, and hydraulic buffers. These systems can effectively reduce the vibration amplitude of the machine, thereby reducing noise generation and ensuring that the equipment is smoother and quieter during operation.

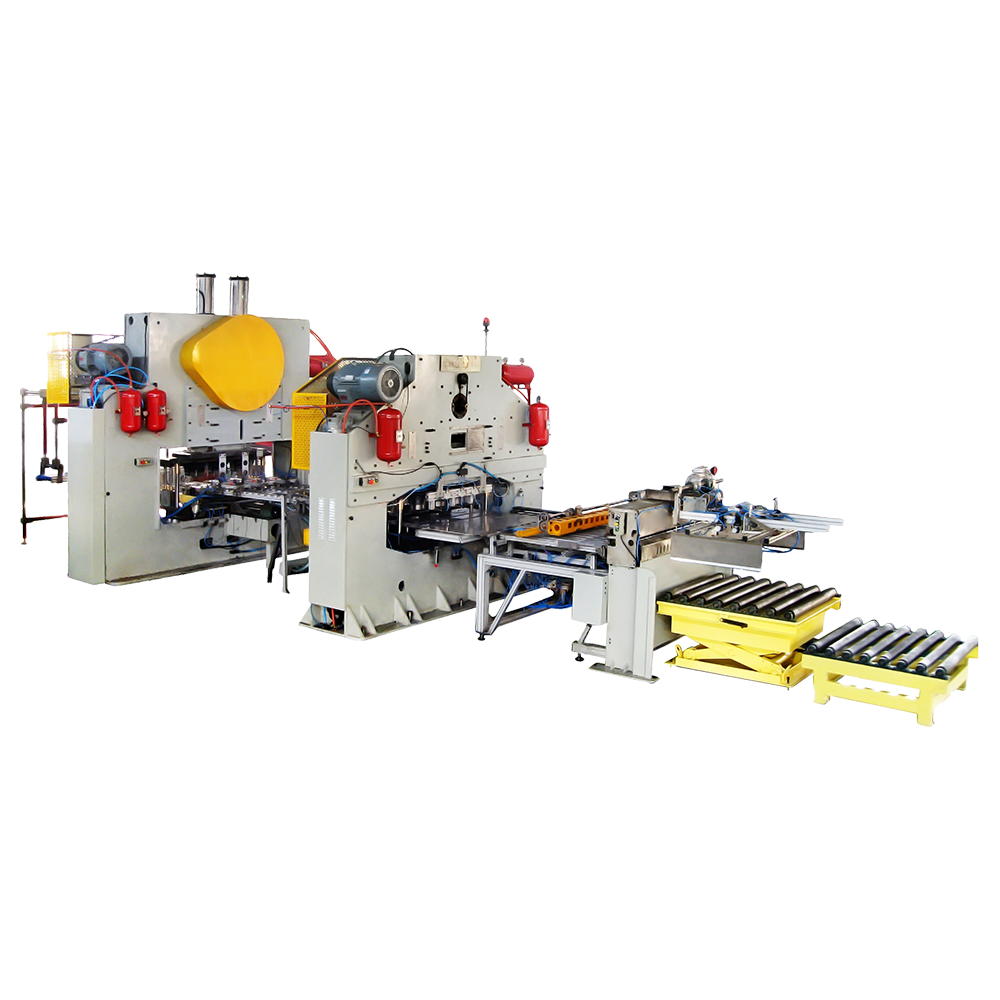

Gears, transmission systems, and hydraulic devices of chemical tank making machines are also common noise sources. To reduce the noise of these components, manufacturers usually choose high-precision, low-noise gears and efficient hydraulic systems. Precision mechanical design can ensure smoother fit between components, reduce friction and impact, and thus reduce noise generation.

If the noise control design is appropriate, the noise level of the chemical tank manufacturing machine can be significantly reduced, ensuring that the production environment meets occupational health and safety standards. For example, the noise standards of many industrial equipment require that the noise during equipment operation does not exceed 85 decibels (dB) to avoid long-term exposure to hearing damage to workers. Therefore, a chemical tank manufacturing machine with good noise control design can not only improve the working environment, but also improve the work efficiency and health level of employees.